Products

Laser Sealing Machine

High energy density, good power stability, high welding precision, and easy system integration

Laser Welding Machine

High energy density, good power stability, high welding precision, and easy system integration

Laser Welding Machine

High energy density, good power stability, high welding precision, and easy system integration

Li-Metal Solid-State Battery Intelligent Line

Integrating Li-metal electrode preparation, stacking, welding, packaging, insulation detection, vacuum electrolyte injection and sealing functions;

The transition chamber has a vacuum baking function;

Water and oxygen content is controlled below 1ppm.

The transition chamber has a vacuum baking function;

Water and oxygen content is controlled below 1ppm.

Lithium Battery Automation Pilot/Production Line in Glove Boxes

This battery automation line in glove boxes can fully automate the production of lithium batteries, greatly improving Pouch cell (vacuum electrolyte filling) production efficiency and saving labor costs.

We are also building a new sample line for this automation line in our Dongguan, Guangdong factory right now.

Lithium Metal Battery Automatic Stacking Machine

The equipment is mainly used in producing pouch cells. It is suitable for making Z-shaped lamination between the positive and negative electrode sheets and the separator. After completing stacking, the hot knife cuts the separator, and the manipulator automatically sends the battery cell to the adhesive position for gluing. Finally, the transfer manipulator completes the unloading of the glued battery cell to the conveyor belt for docking with the next equipment.

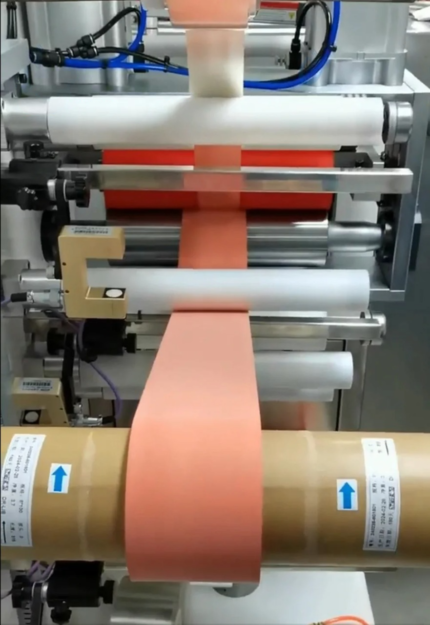

Lithium Metal Electrode Forming Machine

Lithium metal negative electrode automatic forming improves production efficiency, reduces labor costs, and ensures the stability of product quality