Products

Lithium-ion Cylindrical Battery Cell Assembly Solution For Laboratory

Mikrouna Cylindrical Cell Pilot Line for University and R&D laboratory (video attached below):

Cell short circuit test; Tab welding; Assembly of rolling groove; Vacuum baking; Vacuum injection; Standing; Cover (or Closing, if referring to the action of closing the battery); Laser welding cap; Cylindrical sealing

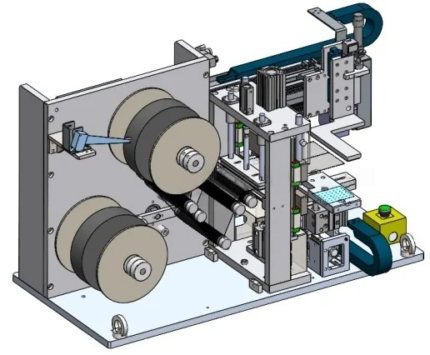

Lithium-ion Cylindrical Battery Cell Laboratory Pilot Line Solution

Mikrouna Cylindrical Cell Pilot Line for University and R&D laboratory (video attached below):

Cell short circuit test; Tab welding; Assembly of rolling groove; Vacuum baking; Vacuum injection; Standing; Cover (or Closing, if referring to the action of closing the battery); Laser welding cap; Cylindrical sealing

Lithium-ion Pouch Battery Cell Assembly Solution for Laboratory

Mikrouna Pouch Cell Pilot Line Process from Proportioning and Weighing to Grading:

Proportioning and Weighing; Slurring Mixing; Coating; Calendering/Rolling Press; Tab Notching (Die cutting); Negative electrode sheet making/Stacking (Lithium strip cutting mentioned); Hot press test; TAB welding (with packaging process mentioned); Formation; Degassing; Grading

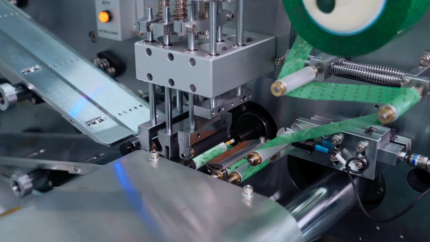

Lithium-ion Pouch Battery Cell Laboratory Pilot Line Solution

Mikrouna Pouch Cell Pilot Line Process from Proportioning and Weighing to Grading:

Proportioning and Weighing; Slurring Mixing; Coating; Calendering/Rolling Press; Tab Notching (Die cutting); Negative electrode sheet making/Stacking (Lithium strip cutting mentioned); Hot press test; TAB welding (with packaging process mentioned); Formation; Degassing; Grading

Moisture Meter

Multi-Channel Energy-Efficient Regenerative Aging and Charging/Discharging Machine

ower supply: Ac voltage 380v ±10%,frequency: 50 Hz±5%Ambient temperature: 0 o 45°c

Ambient humidity: No more than 85%R.H (no condensation)

There is no strong vibration, no corrosive gas and

flammable and explosive gas in the environment

The sampling speed is fast,and the inspection time of the

entire cabinet is less than 8s

Resolution:AD:16bit