Products

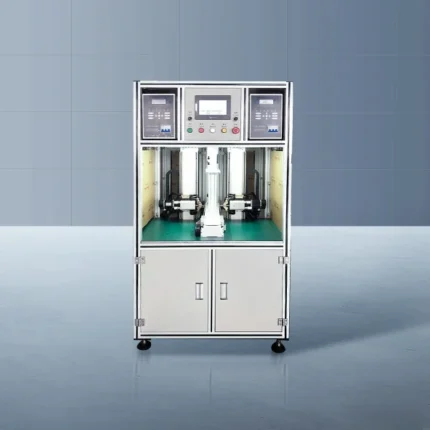

Automatic Spot Welding Machine

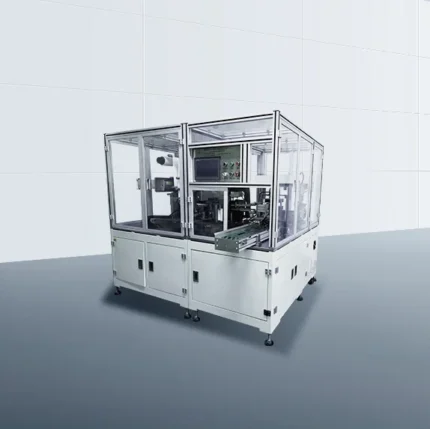

Automatic Stacking Machine

Automatic Stacking Machine for High-Power Lithium-Metal Batteries

Automatic Stacking Machine for High-Power Lithium-Metal Batteries in Drying Room

Designed for the manufacturing of lithium metal battery cells, it enables the automatic stacking of cathode, separators, and lithium metal anode.

Automatic Washer Assembly Machine

Battery Cell PVC Sleeving Machine for Cells with Protection Boards

Battery Electrode Sheet Stacking Machine

The lithium negative electrode adopts single-layer sheet material box to switch manually as the feeding and positioning table, and the material box and the positioning table adopt pin positioning to move to the feeding position (the lithium negative electrode sheet material box is completed by another process); at the same time, it can be compatible with the configuration of graphite and silicon carbon negative electrode material box of the secondary batteries (multi-layer sheet material).

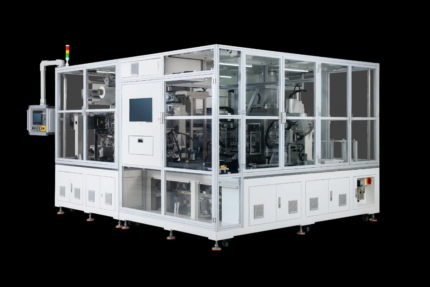

Battery Electrolyte Injection And Sealing Equipment

Vacuum pre-sealing machine, vacuum standing machine, electrolyte injection pump, and heating warehouse are integrated in the vacuum environment created by the glove box. The vacuum degree of the box can reach -0.99KPa to meet sealing requirements of the products.