Products

Multi-type Battery Electrode Coating Machine with Multi-mode (Extrusion, Transfer, Micro-gravure)

This equipment is utilized for the precise coating of lithium-ion battery cathode and anode electrodes. It offers versatile coating modes, including slot die, transfer, and micro-gravure, which are interchangeable and compatible.

The machine primarily comprises an unwinding unit, extrusion coating head, transfer coating head, micro-gravure coating head, slot die feed system, micro-gravure feed system, oven section, NMP recovery system, traction unit, winding unit, and electrical control system.

It uniformly applies the mixed slurry onto the substrate, ensuring that dimensions and weight meet process specifications.

This equipment is an integrated machine with diverse coating methods to cater to various coating process requirements in the lithium-ion battery industry.

Nmp Solvent Recovery System

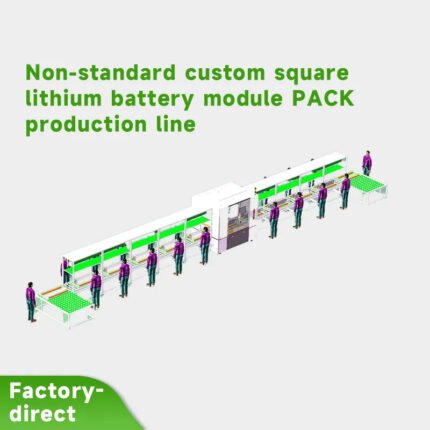

Non-standard Custom Prismatic Lithium Battery Module Pack Production Line

This customized production line is primarily designed for the welding and assembly of prismatic lithium battery pack modules. The line includes: powered roller conveyors (with storage racks and fixture plates), cross-line laser welding, and omnidirectional platforms, among other components.

Non-standard customized prismatic battery cell module PACK production line

This non-standard customized production line is primarily used for the assembly, inspection, and welding of prismatic battery cells in household energy storage modules.

Main Work Stations:

Automatic QR Code Scanning & OCV Sorting

Manual Stacking

Automatic Extrusion & Manual Strapping

Manual Placement of Aluminum Bar

Automatic Laser Welding

Manual Visual Inspection of Welding Quality & Cleaning

Transfer to the Box

PACK Assembly Line

Ocv Sorting Machine

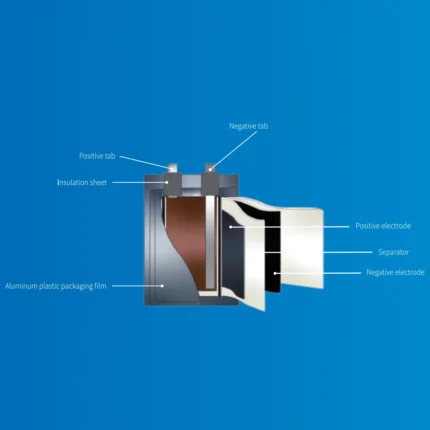

Pouch Battery Preparation Solution

Pre-Weld Polarity CCD Vision Inspection Machine for Battery Modules

Host input power: AC220v/50HZo

Dimensions:950mm(L)*800mm(W)*1800mm(H)

CCD field of view:300mm x320mm

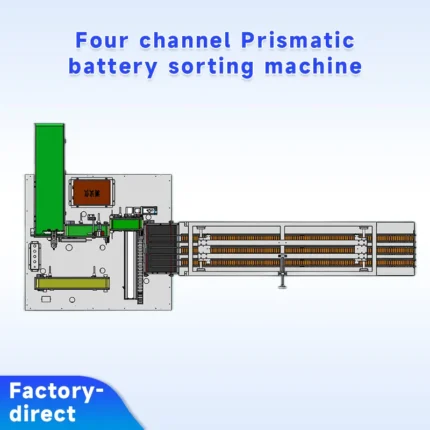

Prismatic Battery 4-Channel Automatic Sorting Machine OCV and IR testing machine

Number of device sorting channels: 3+1(NG) channels

Internal resistance detection accuracy: range 0-60mΩ; Accuracy ±0.5% rdg; Resolution 0.1mΩ

Voltage measurement accuracy: range 0-20V; Basic accuracy ±0.015% rdg; Resolution 0.1mV

NG equipment failure rate: ≤2% (only caused by the equipment)

Product damage probability: ≤0.1%

Equipment capacity speed: 10PPM

Suitable battery type: prismatic battery cell

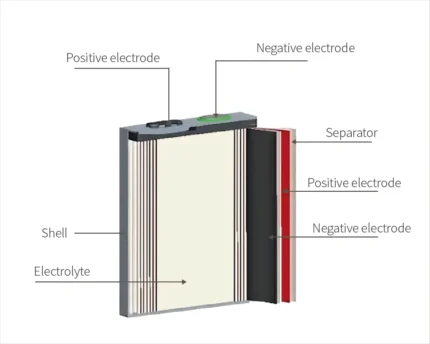

Prismatic Battery Stacking Press Machine for Lithium-Ion Battery Pack Assembly

Module compatible dimensions(mm):length 300-1200/ width 100-300/ height 100-250

Equipment program control mode:PLC control

Extrusion pressure range:0-1000kg

Extrusion stroke range:200-1100mm adjustable

Real-time monitoring of extrusion distance and extrusion pressure dual protection,each parameter can be adjusted by PLC

Equipment dimensions (based on actual conditions):L2330mm*W1000mm*H1536mm

Equipment weight: about 300Kg