Products

Comprehensive Battery Test Equipment for Lithium, Polymer, and Lead-Acid Batteries

Fast and accurate testing of no-load voltage, internal resistance, charging/discharging current, overcurrent protection, short-circuit protection time, and more.

High-performance 32-bit ARM processor and 16-bit AD converter for precise voltage and current measurement.

Simultaneous operation of multiple devices, improving testing efficiency.

Widely used in industries such as automotive electronics, aerospace, solar energy storage, electric bicycles, electric motorcycles…

Core Insertion Machine

Custom Glove Box Solutions

Mikrouna Customized Glove Boxes are modular, high-end containment systems designed for precision operations in controlled environments.

Developed by Mikrouna since 2004, these gloveboxes integrate advanced gas purification, IoT-enabled automation, and multi-industry adaptability, serving as foundational platforms for specialized research and industrial processes

Custom Prismatic Aluminum-Shell Lithium Battery PACK Production Line | Automated Assembly, Testing, and Welding System

Manual loading of battery cells

Automatic cell scanning and 0CV testing and sorting

Manual adhesive application

Manual stacking

Automatic extrusion and compression

Manual application of plastic steel straps

Manual labeling of module codes with a scanner

CCD polarity detection

Manual placement of connection strips

Laser welding

Post-weld visual inspection by hand

Overhead conveyor for transferring to the next line

The PACK section uses a manual non-powered roller conveyor system.

Custom Semi-Automated Lithium Battery PACK Production Line | Air & Liquid Cooling System Assembly, Welding & Testing

Automatic pallet up/down circulation

Automatic voltage and internal resistance sorting of battery cells

Manual adhesive application

Manual stacking

Automatic extrusion and compression

Manual fixing and placement

Manual barcode scanning and module barcode binding

Manual placement of current collection strips

Laser automatic welding

Manual visual inspection of weld quality and cleanliness

Overhead conveyor for line transfer

Manual PACK assembly line

PACK offline process

Cutting, Folding And Ironing Integrated Machine

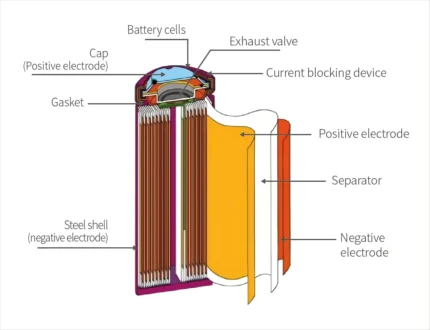

Cylindrical Battery Preparation Solution

Cylindrical Battery Testing Machine (Without Material Hopper)

Technical parameters of voltage measurementVoltage measurement resolution:0.1MA

3561 Battery measuring instrument voltage range:19.9999v

Accuracy:±0.025%R.D.±6dgt

Internal resistance measurement technical parameters

Internal resistance measurement resolution:0.1m

3561 Battery tester resistance range:310.00mQ/3.1000n

Accuracy:±0.025%R.D.±6dgt

Internal resistance measurement frequency:

1KHz± 0.2KHz(AC four-terminal method)

Test efficiency: trouble-free operation

design capacity 2500-3000 Pcs/hour

Cylindrical Battery Testing Machine with Material Hopper

Input power supply:single-phase to 220V/50Hz

Dimensions:1415mm(L)*675mm(W)*1705mm(H)

Access pipe:Ф10mm (outer diameter)

Air source pressure:0.4~0.6MPa

Weight:165KG

Power:1.5KW

Digital Rotational Viscometer

Double planetary mixer

Dual-axis planetary mixing with no dead ends; the mixer is made of high-quality SUS304 stainless steel, resistant to acid and alkali corrosion

Double-Sided Automatic Spot Welder for Power Battery Packs with Nickel Tab Welding

Model: SKXD-700L

Power Supply: AC220V/AC380V, 50/60Hz

Power: 1.5kW

Noise: <60dB

Dimensions: 1800L x 1000W x 1800H mm

Free Stroke: 600mm x 310mm

Weight: 260kg

Nickel Tab Loading Specifications: Thickness 0.1–0.2mm (For sizes beyond this range, process confirmation is required)

Production Efficiency: 3500 pieces/h

Positioning Accuracy: 0.05mm

Control System: PLC + Human-Machine Interface

Programming Interface: Full Chinese LCD Interface