Products

Double, Multi-station Vacuum Glove Box With Water & Oxygen Purification System For Battery Research Laboratory

Introducing Mikrouna’s Vacuum Glove Box System, specifically designed for lithium battery laboratory research and development. This innovative solution offers performance and versatility, catering to the stringent requirements of the lithium battery industry.

Dry Electrode Making for Solid-State Battery

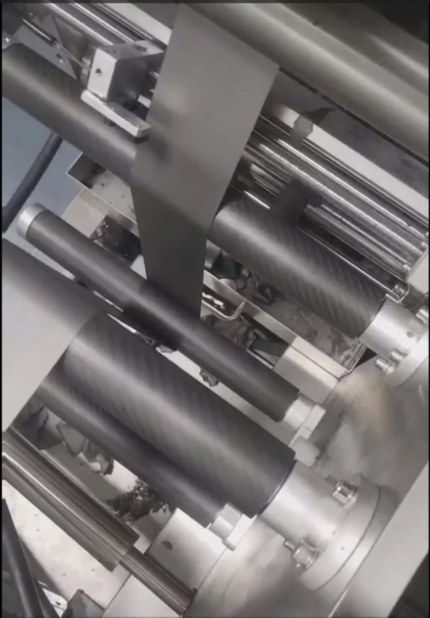

Mikrouna’s dry electrode technology presents a new approach. It includes high-speed mixing of the PTFE binder, active material, and conductive agent, subsequently pressing the mixture through the roller press machines. This semi-finished product is then laminated with a current collector foil coated with conductive adhesive to produce a dry electrode sheet. A notable advantage of this process is its minimal reliance on organic solvents, which is instrumental in enhancing the battery’s capacity and cycle life.

The transformation from dry electrode powder to dry electrode film encompasses three pivotal steps:

1. Compaction of Dry Electrode Powder: The dry electrode powder is pressed into a thin, semi-finished dry electrode film.

2. Rolling to Desired Thickness: This semi-finished film undergoes rolling to attain the specified thickness.

3. Lamination Process:

(1) Conductive Adhesive Coating: The current collector foil is coated with a layer of conductive adhesive.

(2) Lamination: The semi-finished dry electrode film is then laminated with the coated current collector foil to complete the dry electrode sheet.

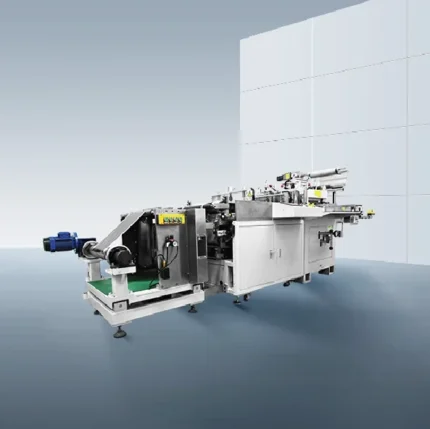

Electrode Cutting Machine

It is specifically designed for precise cutting and forming of pouch battery electrodes. Accurate and uniform cutting can ensure the electrode assembly of pouch batteries and help to produce stable and reliable batteries for consumer electronics, electric vehicles, energy storage systems and various applications

Energy-saving Feedback Capacity Grading Equipment

EOL Test Cabinet for Battery Capacity, Internal Resistance, and Insulation Testing

Equipment working temperature: 0~40°C

Adaptable humidity: 10%~70%R.H. (no condensation)

Power supply:AC220V, 50±2 Hz

Atmospheric pressure: 90~105kPa

Charge and discharge output: DC100V/400A

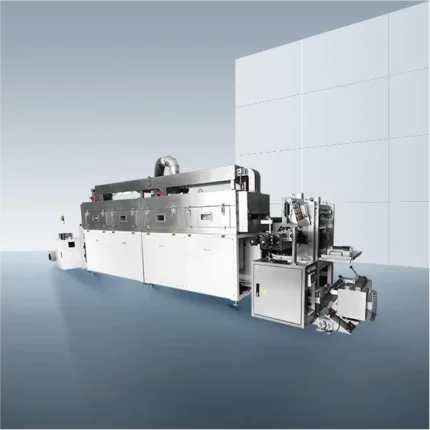

Extrusion Coating Machine

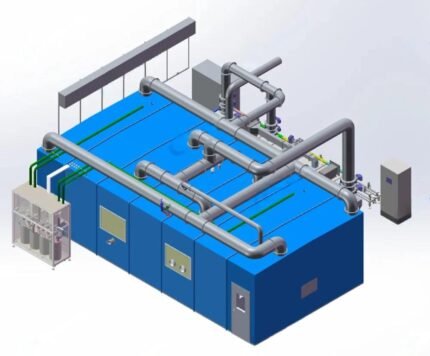

Glove Box For Lithium Battery Producttion

The production line can realize fully automatic scanning – liquid injection – weighing – replenishment – sealing in the super purified glove box, realizing efficient and completely unmanned automatic production, greatly saving labor cost, greatly improving production capacity and product quality and yield rate, maximizing benefits for customers, this production line is a revolution in lithium/supercapacitor production.