Products

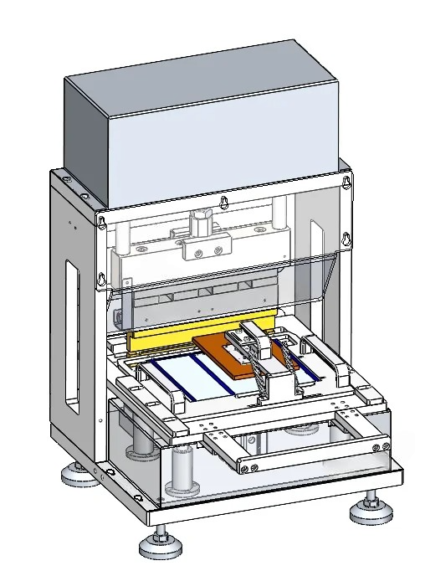

Top And Side Seal Testing Machine

Specially designed for comprehensive testing of top and side seals of aluminum plastic film packaging, it provides accurate and reliable seal testing to ensure the integrity and leak-proofness of packaging seals in a single integrated system, and can evaluate the integrity and reliability of top and side seals of pouch during production

Transfer/extrusion Coating Machine

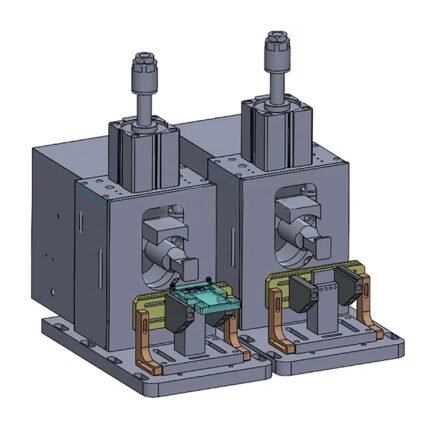

Transistor-based Gantry Pneumatic Battery Spot Welder For Battery Manufacturing

Supply voltage: 220V/380V

Air source pressure: 0.5-0.6MPa

Welding time: 1.0-20.0ms adjustable

Maximum output power: 20 KVA

Maximum short circuit current: 5000A

Welding voltage: 80.0-330V adjustable

Nickel sheet thickness: 0.08mm-0.3mm

Machine weight: 50kg

Machine size: 350*1 80*380cm

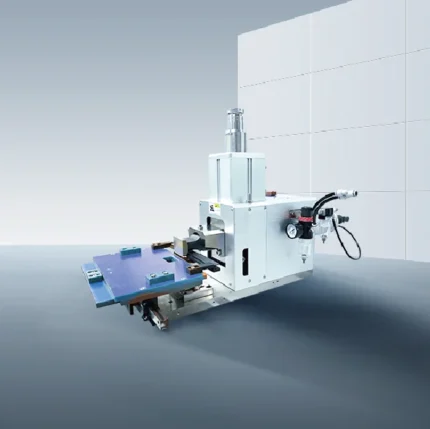

Ultrasonic Welding Machine

Universal 5-Channel 18650,21700,32700 Cylindrical Battery Sorting Machine

Applicable cell:18650,21700,32700 cell

Input Power Supply:Single-phase 220V/50Hz

Dimensions:1200mm (L) x 550mm (W) x 1400mm (H)

Access Pipe:P10mm (outer diameter)

Air Source Pressure:0.4 ~ 0.6 MPa

Weight:180 kg

Universal Glove Box For Lithium Battery R&d And Small Scale Production

From single to multiple workstations, the Mikrouna Universal glove box provides you with the space and systems needed to maintain your inert environment while still allowing production-scale use. All Universal glove boxes provide an integrated gas purification system, PLC-controlled electronics, as well as an HMI touchscreen. Each workstation includes replaceable sight glass, as well as (4) KF40 feedthrough ports. Our standard configurations include transfer antechambers, as well as an Edwards vacuum pump.

All Mikrouna Universal Glove Boxes have an attainable purity level of <1 PPM of O2 and H2O.