Products

Adhesive Application Machine

It is designed for precise adhesive application and sealing of pouch batteries and used to accurately apply adhesive to the tabs for precise and even gluing, and ensure optimal adhesion and protection of battery components.

All-Solid-State-Battery Pouch Cell Dry Preparation Pilot Line

Designed for cutting-edge research and development in solid-state battery technology. Our glove boxes maintain H2O and O2 levels below 1PPM, ensuring safety and stability throughout the battery manufacturing process in the SSB pilot line.

The Mikrouna Solid-State Battery Pilot Line employs advanced dry and wet processes to ensure the high-performance manufacturing and stability of solid-state batteries.

Additionally, our SSB pilot line is fully customizable, making it ideal for supporting batteries with different material systems, including lithium metal anode, Polymer, oxide, and sulfide solid-state batteries.

Main sections:

– Preparation of Solid Electrolyte Materials: Precise weighing & proportioning, vacuum stirring;

– Preparation of Electrolyte Membranes: 3D printing molding / extrusion coating, roll pressing;

– Preparation of Electrode Sheets: Coating & baking, die-cutting & shaping, pressing copper tabs onto lithium foil;

– Assembly of Solid-State Batteries: Semi-automatic stacking, hot pressing test, ultrasonic welding, top & side sealing, vacuum electrolyte filling & sealing.

Integrating Lithium metal electrode preparation, stacking, welding, packaging, insulation

detection, vacuum electrolyte injection, and sealing functions;

The transition chamber also has a vacuum baking function;

Water and oxygen content atmosphere for the Lithium metal solid state battery line inside the glove boxes are controlled below 1ppm.

Aluminum Plastic Film Forming Machine

Specially designed for precise punching and forming of aluminum plastic film casings, it is a critical part in the battery production process. Correctly formed and laminated aluminum plastic film provides an effective barrier to protect the internal components of the battery and ensure the integrity of the battery

Aluminum Shell Prismatic Lithium Battery Extrusion Machine Prismatic Cell Pressing Machine

Manual stacking of end plates, insulating boards, and single battery cells on the platform.

Press the start button to initiate automatic extrusion by the electric cylinder, controlled by the PLC system via pressure sensors.

Stop when force or distance reaches preset values.

Secure with steel straps, then press the retraction button to return the cylinder to standby.

The stacking, extrusion, and bundling process is complete.

Auto Degas Machine for Pouch Cell

Auto Electrolyte Injection Machine for Pouch Cell

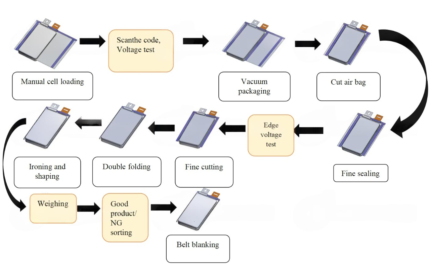

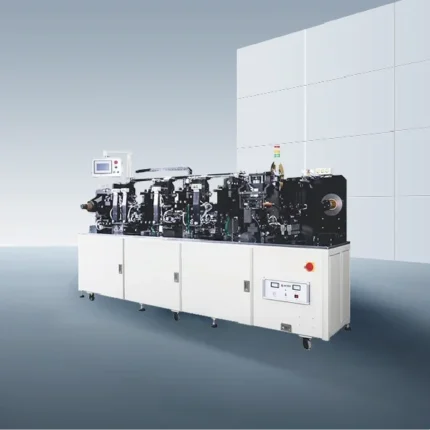

Auto Packaging Machine for Pouch Cell

Auto Welding Machine for Pouch Cell

Automatic 18650 and 21700 Cylindrical Battery Insulation Paper and PVC Applicator

Equipment Name:SKXD-350 Universal Auxiliary Material Applicator

Applicable Battery:18650/21650/21700 Cylindrical Batteries

Surface Padding Material: Insulation Paper or PVC Material(Max Roll Diameter: 350mm,Core Inner Diameter: 72-75mm,Width: 100mm)

Production Efficiency:4,000 pcs/h

Air Pressure:

0.4-0.6 MPa

Input Power Supply:

Single-phase 220V/50Hz

Equipment Power:

Automatic Die Cutting Machine

Automatic Electrode Preparation Machine

It is used for efficient and precise manufacturing of electrodes used in various electrochemical devices such as batteries and capacitors and automatically completes the forming and shaping process from raw materials to electrodes, ensuring consistent quality and precision of the final products to meet the growing demand for high-performance electrochemical equipment across industries

Automatic Electrolyte Filling Machine

Introducing our Mikrouna Automatic Electrolyte Filling Machine, specifically designed for streamlining the liquid injection and packaging process of pouch cell lithium-ion batteries. This machine seamlessly integrates Manual Battery Loading, Pre-injection Weighing, Automatic Electrolyte Filling, Automatic Battery Standing, and Automatic Vacuum Sealing, among other key functions, to enhance production efficiency and quality control.