Battery Automation Solutions

Battery Pack Disassembly Production Line for Used Power Battery Packs

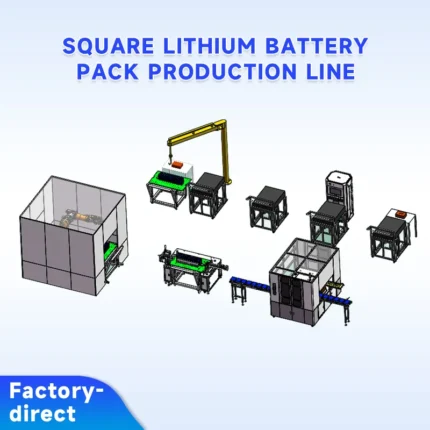

Custom Prismatic Aluminum-Shell Lithium Battery PACK Production Line | Automated Assembly, Testing, and Welding System

Manual loading of battery cells

Automatic cell scanning and 0CV testing and sorting

Manual adhesive application

Manual stacking

Automatic extrusion and compression

Manual application of plastic steel straps

Manual labeling of module codes with a scanner

CCD polarity detection

Manual placement of connection strips

Laser welding

Post-weld visual inspection by hand

Overhead conveyor for transferring to the next line

The PACK section uses a manual non-powered roller conveyor system.

Custom Semi-Automated Lithium Battery PACK Production Line | Air & Liquid Cooling System Assembly, Welding & Testing

Automatic pallet up/down circulation

Automatic voltage and internal resistance sorting of battery cells

Manual adhesive application

Manual stacking

Automatic extrusion and compression

Manual fixing and placement

Manual barcode scanning and module barcode binding

Manual placement of current collection strips

Laser automatic welding

Manual visual inspection of weld quality and cleanliness

Overhead conveyor for line transfer

Manual PACK assembly line

PACK offline process

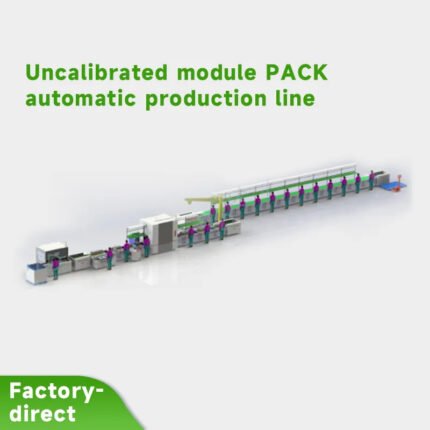

High-Efficiency Prismatic Battery Pack Production Line

Productivity index:Efficiency beat: 3min processing a module

(based on the 1P13S module)

Yield: primary yield is 98.5%,secondary yield is 99.9%

Total power:≤40KW

Device dimensions: The actual layout prevails

Equipment warranty:1 year,laser 2 years

Ambient temperature:5°C-35C Humidity:20%-90%

Air source pressure:0.5~0.6Mpa

Power supply voltage:220V-380V-50Hz/60Hz

Area bearing ratio:≤500kg/M?

Grounding type:direct grounding

Installation environment: flat,no vibration and impact

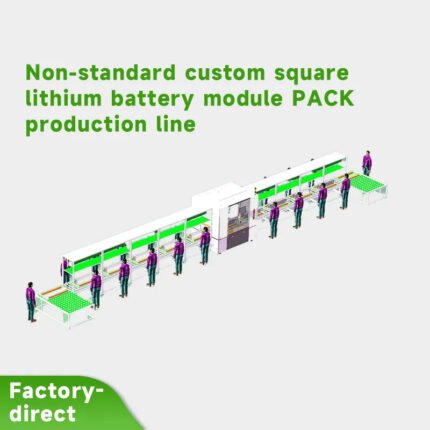

Non-standard Custom Prismatic Lithium Battery Module Pack Production Line

This customized production line is primarily designed for the welding and assembly of prismatic lithium battery pack modules. The line includes: powered roller conveyors (with storage racks and fixture plates), cross-line laser welding, and omnidirectional platforms, among other components.

Non-standard customized prismatic battery cell module PACK production line

This non-standard customized production line is primarily used for the assembly, inspection, and welding of prismatic battery cells in household energy storage modules.

Main Work Stations:

Automatic QR Code Scanning & OCV Sorting

Manual Stacking

Automatic Extrusion & Manual Strapping

Manual Placement of Aluminum Bar

Automatic Laser Welding

Manual Visual Inspection of Welding Quality & Cleaning

Transfer to the Box

PACK Assembly Line