Glove Box For Lithium Battery Producttion

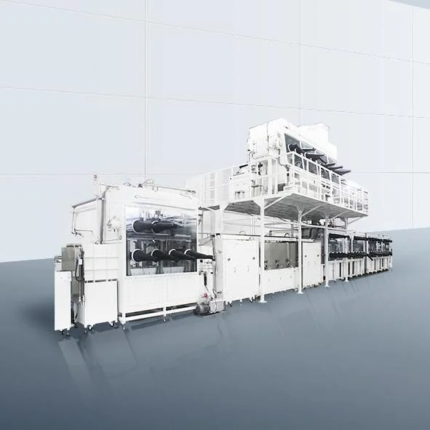

The production line can realize fully automatic scanning – liquid injection – weighing – replenishment – sealing in the super purified glove box, realizing efficient and completely unmanned automatic production, greatly saving labor cost, greatly improving production capacity and product quality and yield rate, maximizing benefits for customers, this production line is a revolution in lithium/supercapacitor production.

Inert gas protection/isolation/vacuum equipment products+Automation Products·Lithium battery automatic production line:

The production line can realize automatic code scanning, injection, weighing, fluid supplementation and sealing in the super-purified glove box, realizing efficient and

completely unmanned automated production, greatly saving labor costs, greatly improving production capacity, product quality and yield, and maximizing benefits for clients.

The production line is a revolution in the production of lithium batteries/supercapacitors.

Lithium Battery Automatic Production Line Function Description:

(1) The battery raw material package enters the glove box from the feed bin;

(2) The battery raw material package is automatically scanned and weighed, and then automatically placed in the material conveying device;

(3) The conveying device automatically sends the package to the injection cylinder for injection;

(4) After injection, the battery enters the standing cylinders 1, 2 and 3 respectively for standing;

(5) After standing, the battery enters the sealing cylinder for vacuuming and sealing;

(6) The sealed battery will be automatically weighed again, and the unqualified product will enter the recycling bin on the left side for treatment;

(7) Qualified batteries will be automatically sent to the discharge bin.

Lithium automatic production line:

The production line can realize fully automatic scanning – liquid injection – weighing – replenishment – sealing in the super purified glove box,

realizing efficient and completely unmanned automatic production, greatly saving labor cost, greatly improving production capacity and product quality and yield rate, maximizing benefits for customers, this production line is a revolution in lithium battery/supercapacitor production.

Lithium metal solid-state battery intelligent equipment line:

– Integrating functions such as lithium metal sheet making, stacking, welding, packaging, insulation detection, and vacuum filling;

– The transition bin has vacuum baking function;

– The content of water and oxygen<1 PPM;

Lithium metal solid-state battery research equipment:

This production line is composed of a four-section glove box system (front round heating bin,rear square transition bin), lithium strip cutting machine, lithium negative electrode sheet making machine (including pasting and pressing tabs, special tooling for turnover), positive electrode sheet punching and cutting, semi-automatic stacking machine, ultrasonic welding machine, top sealing machine, side sealing machine, vacuum filing machine, vacuum pre-sealing machine, etc. to realize the functions of different dehumidification systems.

Sodium-ion battery automated production line:

For the next generation of energy storage solutions, we offer a complete and advanced sodium-ion battery automated production line. This line independently handles quantitative powder injection, tunnel furnace-type segmented continuous high-temperature heating, quantitative electrolyte liquid injection, automatic sealing and welding, sodium injection with negative electrode heating, and automatic vacuum welding of the annular sealing end cover. The entire process is automated, ensuring seamless transmission and production from start to finish.

WHY CHOOSE US

When you select Mikrouna as your technology provider, you’ll be placing your Glovebox & Lithium Battery infrastructure in the hands of experienced, trained professionals. We take a different approach and the results are clear. People love our team and the services we provide.

Rich Glove Box Experience

We have more than 27 years of glove box manufacturing experience and have been awarded 170 technical patents.

Strong Research & Development Team

Our R & D team is committed to innovative technology. Through comprehensive international technical exchange & collaboration and through continuous application of cutting edge engineering and manufacturing techniques we create “state-of-the-art” products and customized solutions to serve the diverse needs of our client base.

Strict Quality Control Standards

We have deployed an ERP system that vigorously and systematically controls, tracks, and monitors the fulfilment process from placement of an order through design, manufacture delivery, installation & commissioning, and post-sale service.

Advanced Production Equipment

Gantry Machining Centers, CNC Turning Centers, Welding Robots, CNC Press Brake, Laser Cutting Machine and Helium Mass Spectrometer leak detection are among the equipment we use every day to produce our glove boxes. These facilities and equipment not only ensure the consistency of the products, but they also enable us to shorten the prototyping cycle of new product R & D and product customization.

Client Service

The key to our client service is our seamless integration of deep industry and functional expertise with tools and capabilities to support execution and make change happen—on a global scale.

|

|

|

|

|

|

|

|

|

|

Reviews

Clear filtersThere are no reviews yet.