Custom Semi-Automated Lithium Battery PACK Production Line | Air & Liquid Cooling System Assembly, Welding & Testing

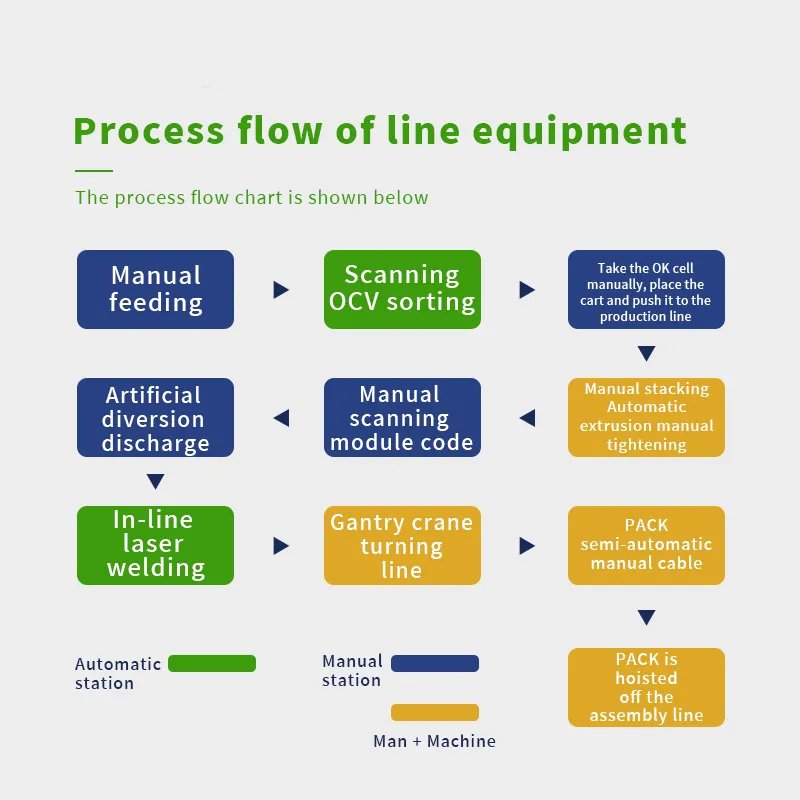

Automatic pallet up/down circulation

Automatic voltage and internal resistance sorting of battery cells

Manual adhesive application

Manual stacking

Automatic extrusion and compression

Manual fixing and placement

Manual barcode scanning and module barcode binding

Manual placement of current collection strips

Laser automatic welding

Manual visual inspection of weld quality and cleanliness

Overhead conveyor for line transfer

Manual PACK assembly line

PACK offline process

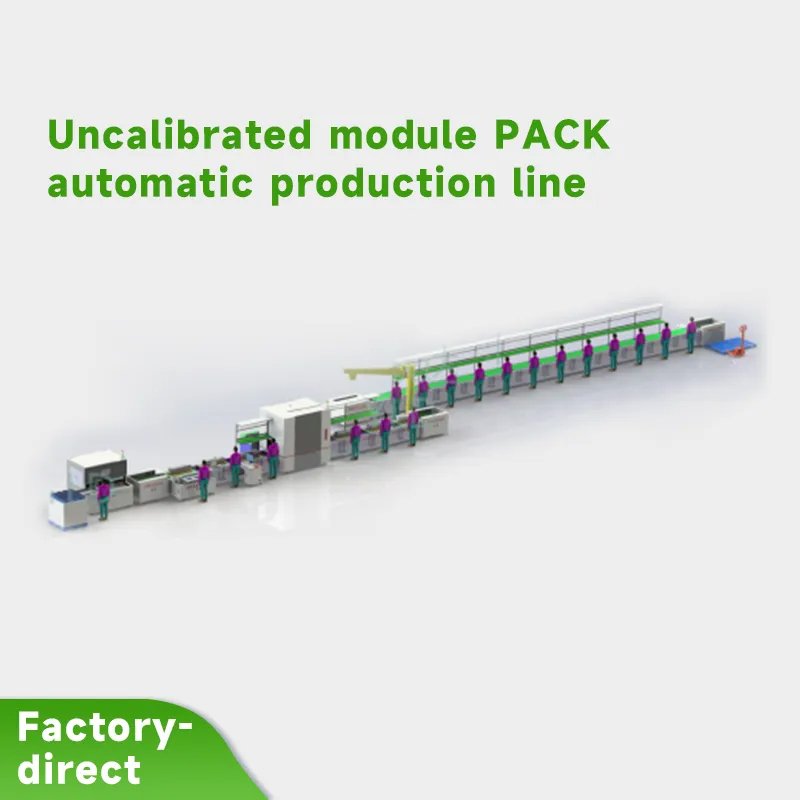

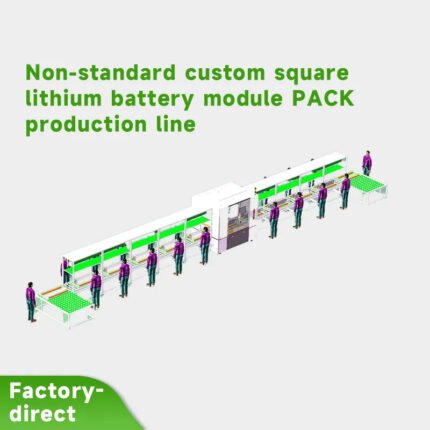

Custom Semi-Automated Lithium Battery PACK Production Line

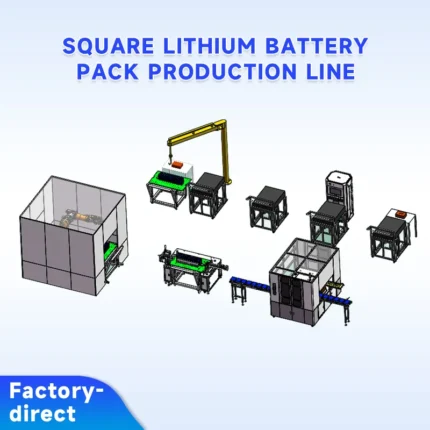

This semi-automated production line is designed for efficient and precise lithium battery PACK assembly, integrating air & liquid cooling system assembly, welding, and testing.

Key processes include:

- Automatic pallet up/down circulation for streamlined handling

- Automatic voltage and internal resistance sorting to ensure battery consistency

- Manual adhesive application and stacking for secure assembly

- Automatic extrusion and compression for uniform PACK formation

- Laser automatic welding for high-precision connections

- Manual visual inspection of weld quality and cleanliness

- Overhead conveyor system for smooth line transfer

- Manual PACK assembly and offline processing for final quality checks

This customizable solution enhances productivity and quality control, making it ideal for high-performance lithium battery PACK manufacturing.

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.