Dry Electrode Film Preparation

Dry Electrode Making for Solid-State Battery

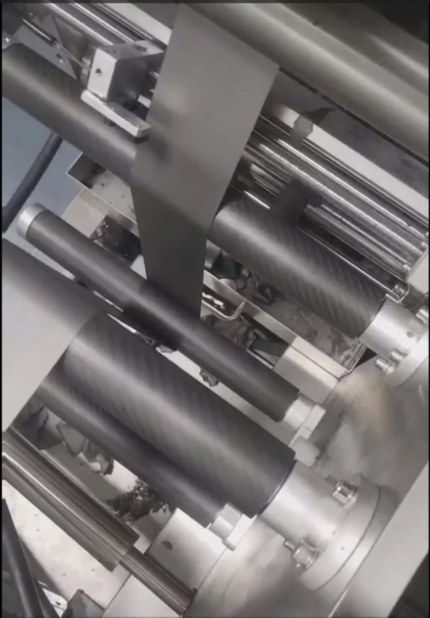

Mikrouna’s dry electrode technology presents a new approach. It includes high-speed mixing of the PTFE binder, active material, and conductive agent, subsequently pressing the mixture through the roller press machines. This semi-finished product is then laminated with a current collector foil coated with conductive adhesive to produce a dry electrode sheet. A notable advantage of this process is its minimal reliance on organic solvents, which is instrumental in enhancing the battery’s capacity and cycle life.

The transformation from dry electrode powder to dry electrode film encompasses three pivotal steps:

1. Compaction of Dry Electrode Powder: The dry electrode powder is pressed into a thin, semi-finished dry electrode film.

2. Rolling to Desired Thickness: This semi-finished film undergoes rolling to attain the specified thickness.

3. Lamination Process:

(1) Conductive Adhesive Coating: The current collector foil is coated with a layer of conductive adhesive.

(2) Lamination: The semi-finished dry electrode film is then laminated with the coated current collector foil to complete the dry electrode sheet.