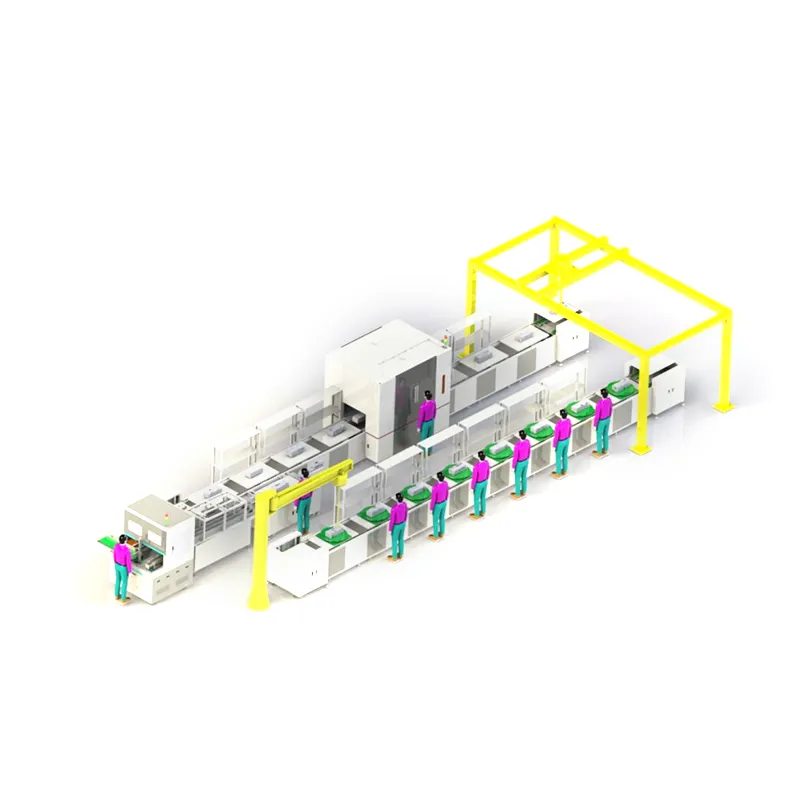

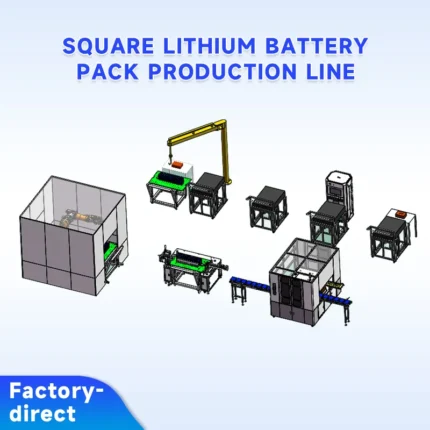

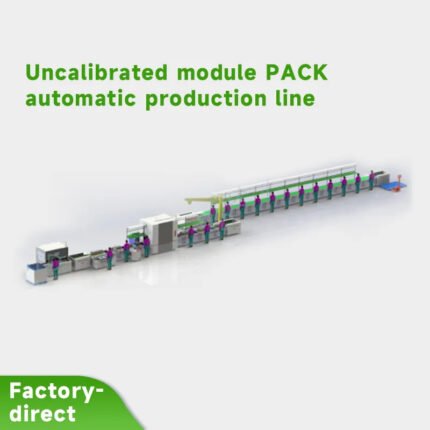

Non-standard customized prismatic battery cell module PACK production line

This non-standard customized production line is primarily used for the assembly, inspection, and welding of prismatic battery cells in household energy storage modules.

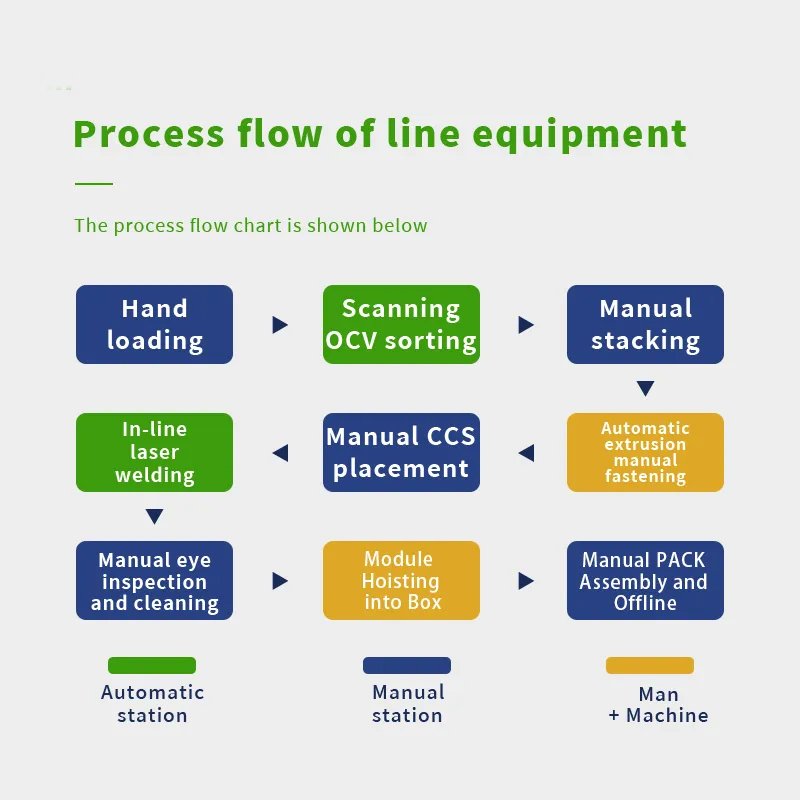

Main Work Stations:

Automatic QR Code Scanning & OCV Sorting

Manual Stacking

Automatic Extrusion & Manual Strapping

Manual Placement of Aluminum Bar

Automatic Laser Welding

Manual Visual Inspection of Welding Quality & Cleaning

Transfer to the Box

PACK Assembly Line

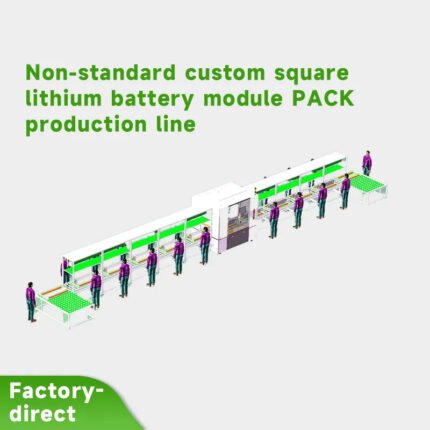

Non-Standard Customized Prismatic Battery Cell Module PACK Production Line

This custom production line is specifically designed for assembling, inspecting, and welding prismatic battery cells used in household energy storage modules. It ensures precision, efficiency, and high-quality output in battery PACK manufacturing.

Main Work Stations:

-

Automatic QR Code Scanning & OCV Sorting

-

Manual Stacking of Battery Cells

-

Automatic Extrusion & Manual Strapping

-

Manual Placement of Aluminum Bar

-

Automatic Laser Welding for Strong, Reliable Connections

-

Manual Visual Inspection of Welding Quality & Cleaning

-

Transfer to the Box for Further Processing

-

Final PACK Assembly Line

This flexible and scalable production line meets non-standard requirements, ensuring high efficiency and reliability in energy storage module manufacturing.

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.