Transistor-based Gantry Pneumatic Battery Spot Welder For Battery Manufacturing

Supply voltage: 220V/380V

Air source pressure: 0.5-0.6MPa

Welding time: 1.0-20.0ms adjustable

Maximum output power: 20 KVA

Maximum short circuit current: 5000A

Welding voltage: 80.0-330V adjustable

Nickel sheet thickness: 0.08mm-0.3mm

Machine weight: 50kg

Machine size: 350*1 80*380cm

Transistor-Based Gantry Pneumatic Battery Spot Welder for Battery Manufacturing

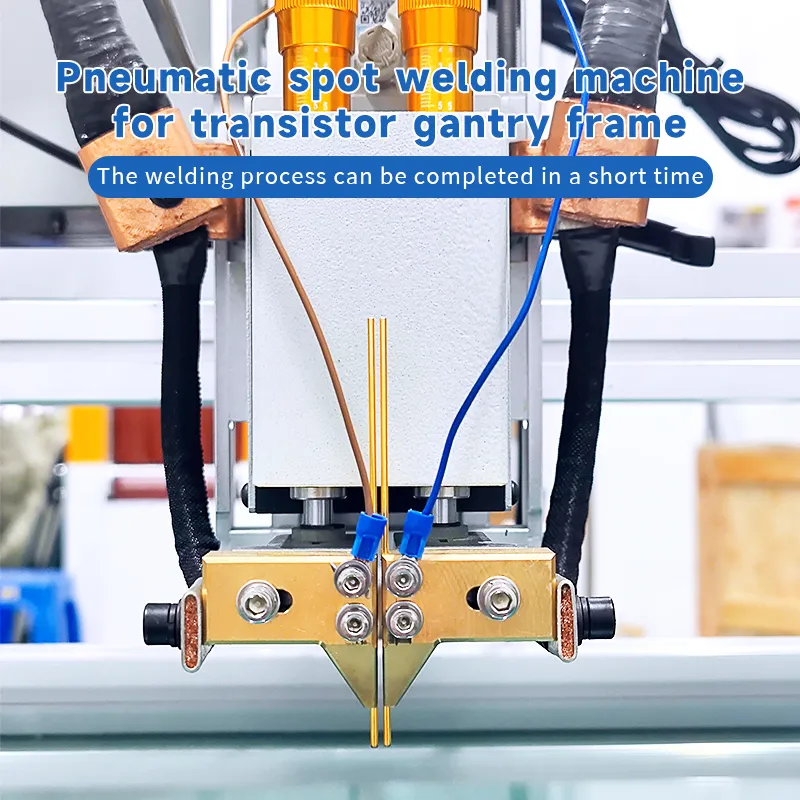

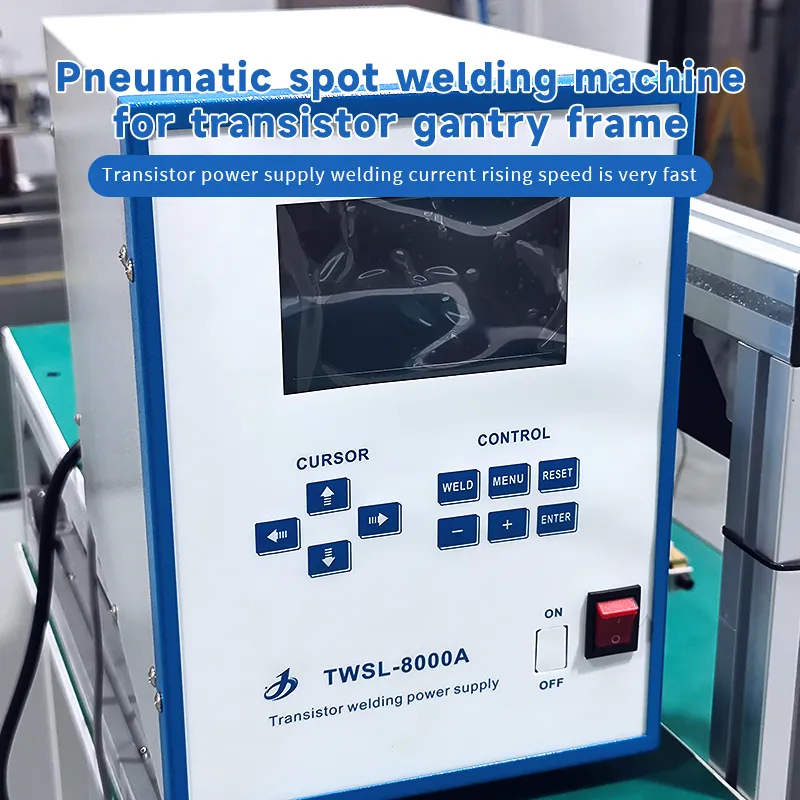

The TWSL-50 Transistor-Based Gantry Pneumatic Battery Spot Welder is an advanced welding solution designed for high-precision battery manufacturing. This machine ensures consistent, strong welds while offering adjustable welding parameters to accommodate different battery production needs.

With a maximum output power of 20 KVA and a short circuit current of up to 5000A, the TWSL-50 delivers efficient and reliable welding for nickel sheet thicknesses ranging from 0.08mm to 0.3mm. Its adjustable welding voltage (80.0-330V) and precise timing control (1.0-20.0ms) allow for superior welding accuracy.

The machine operates with an air source pressure of 0.5-0.6MPa and is compatible with 220V/380V power supply, making it suitable for various industrial battery assembly applications.

Key Features:

- Transistor-based welding technology for high precision and stability.

- Adjustable welding voltage (80.0-330V) and timing (1.0-20.0ms) for customized performance.

- Handles nickel sheet thicknesses from 0.08mm to 0.3mm.

- Maximum output power of 20 KVA and short circuit current of 5000A for strong, durable welds.

- Compact and lightweight design (50kg) for easy integration into production lines.

Ideal for battery pack manufacturers, the TWSL-50 ensures superior spot welding quality, enhanced production efficiency, and long-term reliability.

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.