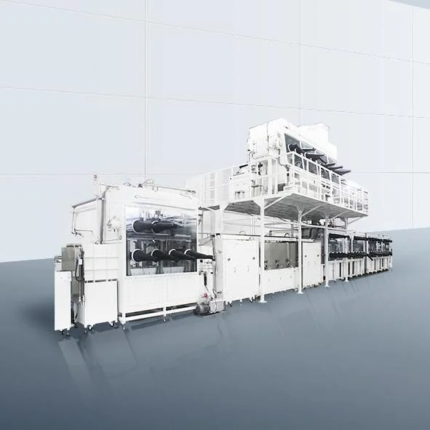

Universal Glove Box For Lithium Battery R&d And Small Scale Production

From single to multiple workstations, the Mikrouna Universal glove box provides you with the space and systems needed to maintain your inert environment while still allowing production-scale use. All Universal glove boxes provide an integrated gas purification system, PLC-controlled electronics, as well as an HMI touchscreen. Each workstation includes replaceable sight glass, as well as (4) KF40 feedthrough ports. Our standard configurations include transfer antechambers, as well as an Edwards vacuum pump.

All Mikrouna Universal Glove Boxes have an attainable purity level of <1 PPM of O2 and H2O.

The Mikrouna Universal Glove Box is commonly used in Research & Development Applications and Small Scale Production Enviroments:

From single to multiple workstations, the Mikrouna Universal glove box provides you with the space and systems needed to maintain your inert environment while still allowing production scale use. All Universal glove boxes provide an integrated gas purification system, PLC controlled electronics, as well as an HMI touchscreen. Each workstation includes replaceable sight glass, as well as (4) KF40 feedthrough ports. Our standard configurations include transfer antechambers, as well as an Edwards vacuum pump.

All Mikrouna Universal Glove Boxes have an attainable purity level of <1 PPM of O2 and H2O.

Mikrouna Glove Box Advantages:

– High Capacity Purifier

Rapid removal of H2O and O2 to less than 1ppm

Long intervals between regeneration cycles.

– PLC Control and Color Touchscreen HMI

Automatic Purge; Circulation; Regeneration; Pressure control; User Friendly Interface.

– Long Life Moisture and Oxygen Analyzers

P2O5 Moisture Sensor: Corrosion resistant, Renewable by acid-cleaning if the probe is contaminated by HF or other corrosive environmental exposure.

ZrO2 Oxygen Sensor: Solid sensor, long life, can be exposed to air without consumption.

– Customize a glove box specially for your application

Our engineering team can help to turn your idea into a solution.

– Stainless Steel gas pipes and connectors

All the gloveboxes has been upgrade to stainless steel pipes and connectors with much higher corrosive-proof for highly corrosive environment.

Technical Specifications:

| Component | Description |

| Main Chamber | |

| Modular Length | 1220mm/1500mm/1800mm/2440mm (48.0”/59.1”/70.9”/96.0”) |

| Modular Depth | 750mm/1000mm/1200mm (29.5”/39.4”/47.2”) |

| Modular Height | 900mm (35.4”) |

| Material | Stainless steel type 304, thickness 3mm (1/8”) |

| Sight Windows | Inclined, Safety Glass, thickness 8mm (1/3”) |

| Gloves Ports | POM (Polyoxymethylene), 220mm (8.7”) Diameter |

| Gloves | 8B1532 |

| Dust Filter | HEPA 0.3μ, one gas inlet, one gas outlet |

| Shelving | Stainless Steel, two fixed shelves (adjustable shelves available) |

| Lighting | External LED lights, front mounted above sight glass |

| Feedthroughs | One power feedthrough, 3 blind-flanges |

| Large Antechamber | |

| Diameter | 360mm (14.2”) or 400mm (15.7”) |

| Length | 600mm (23.6”) |

| Features | With Sliding tray, Spindle lock door, Vertical operation with lifting mechanism, Automatic operation via solenoid valves |

| Small Antechamber | |

| Diameter | 150mm (5.9”) or 100mm (3.9”) |

| Length | 300mm (11.8”) |

| Features | Hinged door, Manual operation via hand valve |

| Purifier | |

| Function | Removal of H2O and O2 to Less than 1 ppm moisture and oxygen |

| Absorber Unit | 5kg Copper catalyst, 5kg Molecular sieve |

| Capacity | Oxygen removal: 60L, Moisture removal: 2000g |

| Encapsulated Blower | 90m3/h |

| Regeneration | PLC control all process including heating, introducing mix gas (working gas mixed with Hydrogen 5-10%), etc. |

| System Control | |

| PLC and HMI | Siemens S7 |

| Vacuum Pump | |

| Type | 8m3/h Rotary vane pump |

| Features | Oil mist filter, Gas ballast |

Options & Accessories:

(1) Enhanced Accessories:

– Moisture Sensor: Ensuring precise moisture level monitoring within the environment.

– Oxygen Sensor: Maintaining accurate oxygen control for sensitive applications.

– Solvent Absorber: Efficiently absorbing solvent vapors to preserve purity.

– Heated Antechamber: Preconditioning samples in a temperature-controlled environment.

– Refrigerator: Integrated cooling system for temperature-sensitive experiments.

– Cold Well: Providing additional cooling capacity for demanding procedures.

– Microscope Unit: Facilitating precise observations and inspections.

– Ionizer (Fanless): Eliminating static electricity without disruption from fan noise.

– Versatile Feedthroughs: Accommodating various connections and cables for seamless integration.

(2) Tailored Options for Ultimate Flexibility:

– Custom Box Dimensions: Crafted to fit your unique experimental requirements.

– Instrument Integration: Seamlessly integrate your evaporator, ALD System, Spin Coater, and more into the glovebox.

– Polycarbonate Windows: High-visibility access panels for easy monitoring.

– Quick Release Windows: Expediting access and reducing downtime.

– Interlocking Door Antechamber: Enhanced safety and controlled entry.

– Sliding Tray Chamber: Compact space optimization for small samples.

– Antechamber Purging (No Vacuum): Cost-effective purge solution.

– Gas Cylinder Refilling: Flexible gas supply directly from cylinders.

– Rectangular Antechamber: Optimized for space-specific configurations.

– Adjustable Shelves: Versatile storage solutions for maximum efficiency.

– 12m³/h Rotary Pump: High-performance vacuum pumping for demanding applications.

– Dry Scroll Pump: Efficient, low-maintenance vacuum generation.

– Prompt Service: Ensuring round-the-clock support for your operational needs.

Glove Box Special for Lithium Battery Experiment:

WHY CHOOSE US

When you select Mikrouna as your technology provider, you’ll be placing your Glovebox & Lithium Battery infrastructure in the hands of experienced, trained professionals. We take a different approach and the results are clear. People love our team and the services we provide.

Rich Glove Box Experience

We have more than 27 years of glove box manufacturing experience and have been awarded 170 technical patents.

Strong Research & Development Team

Our R & D team is committed to innovative technology. Through comprehensive international technical exchange & collaboration and through continuous application of cutting edge engineering and manufacturing techniques we create “state-of-the-art” products and customized solutions to serve the diverse needs of our client base.

Strict Quality Control Standards

We have deployed an ERP system that vigorously and systematically controls, tracks, and monitors the fulfilment process from placement of an order through design, manufacture delivery, installation & commissioning, and post-sale service.

Advanced Production Equipment

Gantry Machining Centers, CNC Turning Centers, Welding Robots, CNC Press Brake, Laser Cutting Machine and Helium Mass Spectrometer leak detection are among the equipment we use every day to produce our glove boxes. These facilities and equipment not only ensure the consistency of the products, but they also enable us to shorten the prototyping cycle of new product R & D and product customization.

Client Service

The key to our client service is our seamless integration of deep industry and functional expertise with tools and capabilities to support execution and make change happen—on a global scale.

Reviews

Clear filtersThere are no reviews yet.