X-ray Inspection Machine

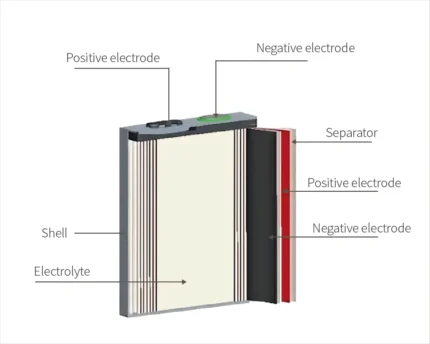

It is used to automatically detect the alignment of the electrodes at the four corners of the battery cell, automatically determine and display the results on the output screen

Category: Prismatic Battery Assembly

Description

GPU and CPU SSE acceleration is applied for fast processing, and all operations can be completed in 200MS when processing a 5-megapixel battery image;

Equipped with 1/100 ultra-high sub-pixel processing cathode and anode detection algorithm and AI multi-layer convolutional neural network joint comprehensive operation, the processing accuracy is high and the anode and cathode points are close to the level of the human eye;

The NG type identification and classification function can accurately identify and classify common NG types such as the alignment of the positive and negative electrodes of the battery, as well as the statistical maximum value, minimum value, mean value, positive electrode difference, and negative electrode difference.

Reviews (0)

Rated 0 out of 5

0 reviews

Rated 5 out of 5

0

Rated 4 out of 5

0

Rated 3 out of 5

0

Rated 2 out of 5

0

Rated 1 out of 5

0

Be the first to review “X-ray Inspection Machine” Cancel reply

Download

Prodcution Line for Intelligent Equipment of Lithium Batteries-新(1).pdf

Download PDF

Reviews

Clear filtersThere are no reviews yet.