Solid State Battery Equipment Pilot Line Solution

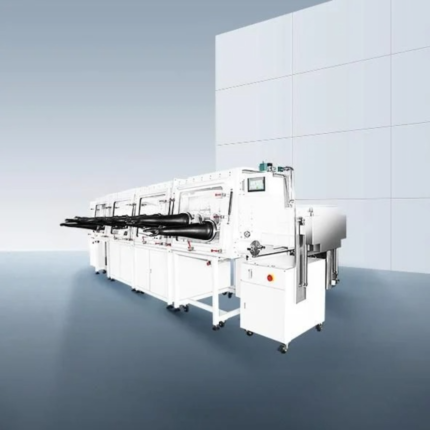

Designed for cutting-edge research and development in solid-state battery technology. Our glove boxes maintain H2O and O2 levels below 1PPM, ensuring safety and stability throughout the battery manufacturing process in the SSB pilot line.

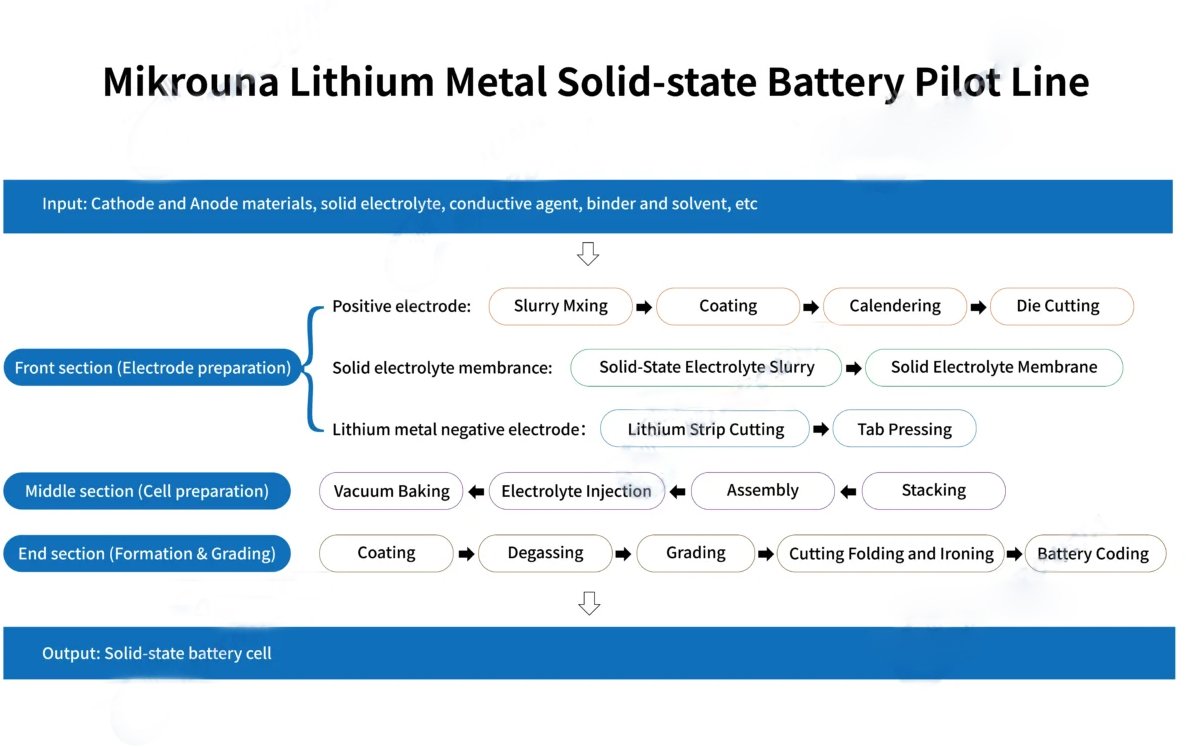

The Mikrouna Solid-State Battery Pilot Line employs advanced dry and wet processes to ensure the high-performance manufacturing and stability of solid-state batteries.

Additionally, our SSB pilot line is fully customizable, making it ideal for supporting batteries with different material systems, including lithium metal anode, Polymer, oxide, and sulfide solid-state batteries.

Main sections:

– Preparation of Solid Electrolyte Materials: Precise weighing & proportioning, vacuum stirring;

– Preparation of Electrolyte Membranes: 3D printing molding / extrusion coating, roll pressing;

– Preparation of Electrode Sheets: Coating & baking, die-cutting & shaping, pressing copper tabs onto lithium foil;

– Assembly of Solid-State Batteries: Semi-automatic stacking, hot pressing test, ultrasonic welding, top & side sealing, vacuum electrolyte filling & sealing.

Integrating Lithium metal electrode preparation, stacking, welding, packaging, insulation

detection, vacuum electrolyte injection, and sealing functions;

The transition chamber also has a vacuum baking function;

Water and oxygen content atmosphere for the Lithium metal solid state battery line inside the glove boxes are controlled below 1ppm.

Designed for cutting-edge research and development in solid-state battery technology. Our glove boxes maintain H2O and O2 levels below 1PPM, ensuring safety and stability throughout the battery manufacturing process in the SSB pilot line.

The Mikrouna Solid-State Battery Pilot Line employs advanced dry and wet processes to ensure the high performance manufacturing and stability of solid-state batteries.

Additionally, our SSB pilot line is fully customizable, making it ideal for supporting batteries with different material systems, including lithium metal anode, Polymer, oxide, and sulfide solid-state batteries.

Main sections:

– Preparation of Solid Electrolyte Materials: Precise weighing & proportioning, vacuum stirring;

– Preparation of Electrolyte Membranes: 3D printing molding / extrusion coating, roll pressing;

– Preparation of Electrode Sheets: Coating & baking, die-cutting & shaping, pressing copper tabs onto lithium foil;

– Assembly of Solid-State Batteries: Semi-automatic stacking, hot pressing test, ultrasonic welding, top & side sealing, vacuum electrolyte filling & sealing.

Energy-saving atmosphere protection system, Material weighing proportion, Vacuum stirring, Coating and baking & 3D printing forming, Rolling Electrode cutting, Lithium foil pressing copper tab, Electrode die cutting and shaping, Lithium metal semi-automatic stacking, Hot press testing, Tab ultrasonic welding, Top-side sealing, Vacuum electrolyte injection, Vacuum sealing, Aluminum-plastic film manual forming (outside the glove box)

It provides a complete set of solutions for lithium metal battery research and development experiments, including lithium metal preparation, lithium metal negative electrode forming and a series of test equipment support.

Lithium Metal Solid State Battery Equipment Line:

Integrating Lithium metal electrode preparation, stacking, welding, packaging, insulation

detection, vacuum electrolyte injection and sealing functions;

The transition chamber also has a vacuum baking function;

Water and oxygen content atmosphere for the Lithium metal solid state battery line inside the glove boxes are controlled below 1ppm.

The Mikrouna Lithium Metal Solid State Battery Line Turnkey Solution is built in the vacuum glove boxes with following optional battery manufacturing processes:

Energy-saving atmosphere protection system; Material weighing proportion; Vacuum stirring; Coating and baking & 3D printing forming; Rolling; Electrode cutting; Lithium foil pressing copper tab; Electrode die cutting and shaping; Lithium metal semi-automatic stacking; Hot press testing; Tab ultrasonic welding; Top-side sealing; Vacuum electrolyte injection; Vacuum sealing; Aluminum-plastic film manual forming (outside the glove box)

FAQ

Q: What are the unique technical features of Mikrouna’s lithium-metal solid-state battery equipment?

A: Our equipment employs advanced solid-state electrolyte preparation technology, enabling high-precision membrane deposition that ensures uniformity and stability of the electrolyte membrane. Additionally, it boasts efficient electrode coating and packaging processes, enhancing battery performance and consistency.

Q: How efficient is Mikrouna’s lithium-metal solid-state battery equipment in production?

A: Our equipment is meticulously designed and optimized for high production efficiency while maintaining product quality. Through automation control and advanced process flows, we significantly reduce production cycles to meet large-scale market demands.

Q: How is the stability and reliability of the equipment ensured?

A: We use high-quality components and materials, subject them to rigorous quality inspections. Extensive reliability testing and optimization are conducted during R&D, complemented by comprehensive after-sales service and technical support to guarantee long-term stability and reliability.

Q: What are the energy-saving advantages of Mikrouna’s equipment?

A: Our equipment adopts an energy-efficient design concept, effectively reducing energy consumption during operation. By optimizing the power system and energy management, we minimize unnecessary energy waste, helping users lower production costs.

Q: Are the operation and maintenance of the equipment complex?

A: We strive to provide user-friendly equipment with a simple and intuitive operation interface, requiring minimal training for operators. Detailed maintenance manuals and training services are also provided to facilitate easy routine maintenance and care.

Q: How does Mikrouna ensure the quality of lithium-metal solid-state batteries produced by its equip

A: The equipment is equipped with high-precision detection and monitoring systems to real-time monitor key production parameters. Coupled with a rigorous quality control system, every batch of products undergoes strict testing to meet high-quality standards.

Q: What about customization services for the equipment?

A: We offer customized equipment solutions tailored to clients’ specific needs and production scales. Whether for small R&D lines or large-scale production lines, we can design the most suitable equipment configurations.

Q: What safety considerations have been incorporated into Mikrouna’s equipment?

A: The equipment features multiple safety protection mechanisms, including overvoltage and overcurrent protection, as well as fire and explosion-proof designs. Adherence to relevant safety standards and regulations throughout production ensures the safety of operators and equipment.

Q: How does Mikrouna handle equipment upgrades and replacements?

A: We continuously invest in R&D, keeping abreast of industry trends and market demands to upgrade and improve our equipment. Upgrade services are provided to ensure that clients’ equipment remains advanced and competitive.

Q: Compared to competitors, what are the advantages of Mikrouna’s equipment?

A: Our equipment excels in technological innovation, performance stability, production efficiency, customization services, and after-sales support. By continuously enhancing our technical capabilities and service levels, we provide clients with more valuable lithium-metal solid-state battery production equipment.

Reviews

Clear filtersThere are no reviews yet.