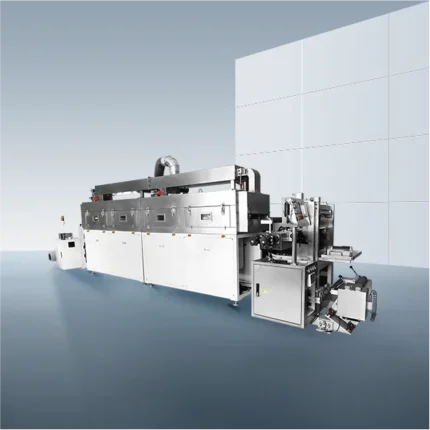

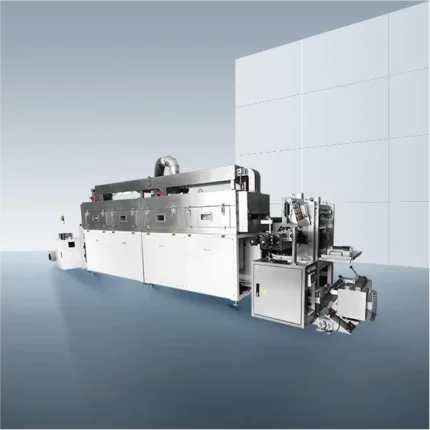

Slot Die Coating Machine

Extrusion coating is a process in which the stirred slurry is extruded to the substrate (such as copper foil or aluminum foil) at a certain pressure and flow rate according to the cell process by the coating head (usually a slit coating head) to form a uniform coating, which is dried in the oven and rewound by traction tension correction and other devices.

Slot Die Coating Machine Flow Chart

– Product specifications, pre-process roll number, meters, shifts, and personnel information enter the MES system;

The size of the large and small cells is calculated from the size chain of the previous process.

– Equipment parameters output MES system: coating air volume, temperature, speed, tension, ẞ-Ray measurement data (mode output discussed with QA), NMP concentration monitoring, pump speed, stirring speed.

(1) Incoming material specifications:

| No. | Project | Cathode |

| 1 | Substrate | aluminum foil |

| 2 | Width (mm) | 150~600 |

| 3 | Thickness (μm) | 10~30 |

| 4 | Outer Diameter(mm) | 80~500 |

| 5 | Weight (kg) | 0~500 |

| 6 | Reel inner diameter | 3 inches |

| 7 | Slurry viscosity (mPa·s) | 4000~12000 |

| 8 | Slurry specific gravity (g/ml) | 1.5~3.0 |

| 9 | Slurry solid content (%) | 52~80 |

| 10 | High slurry temperature (°C) | 22~28 |

| 11 | Slurry fineness (μm) | ≤15 |

| 12 | Iron removal (ppb) | ≤200 |

(2) Equipment technical parameters and energy consumption:

| Technical parameters | |

| Item | Parameter description |

| Device dimensions | Length: ≤28M Width: ≤3M Height: ≤2.7M (Based on the final design)

(With layout drawing, excluding rewinding and unwinding operation area, 2 meters each) |

| Device weight | ≤ 20 tons |

| Device power | Power supply mode: three-phase five-wire power supply (protective grounding), power supply: AC380V, 50/60Hz |

| Pressurized air | A. Compressed air pressure: ≥0.5MPa, air pressure fluctuation ±1% (clean air after water removal, oil-free, filtered and stabilized);

B. Compressed air consumption: 20m³/h, number of interfaces: 2 / set (head, tail); Interface tubing specification: Φ12mm. |

| Device power | Total power (electricity): 170KW; Divided into 1 power supply; |

| Ground bearing and flatness | A. Total weight of equipment: about 15 tons;

B. Cement floor or terrazzo floor, flatness ± 5mm/㎡, bearing capacity ≥ 1000kg/㎡. |

| Acclimatization to ambient temperatures | A. The temperature of the coating head is 25±5°C (according to the buyer’s process requirements), the equipment head is independently isolated, stainless steel is used as the skeleton, and the others are filled with tempered glass, the top air supply outlet is added with a high-efficiency filter, and a return air outlet is added on the side; (Buyer equipped)

B. Cleanliness: 100,000 grade (according to the buyer’s process requirements); |

| Oven air volume | A. Overall maximum air supply volume: Cathode 24000㎥/h;

B. Maximum exhaust air volume of the equipment: 8000㎥/h at the positive electrode. |

| relative humidity | Relative humidity: 1%~30% RCH (according to the buyer’s process requirements); |

| Oven specifications | Each section is 2/m, a total of 8 sections, the total length is 16 meters, and the oven is single-layer |

| Oven heating method | Electrically heated |

| Surface color | Oven frame paint: the buyer provides the color card; Oven box stainless steel primary color; |

| Equipment noise | ≤75db |

| CPK | ≥1.33 |

| Coating width (mm) | Max: 400-600mm; Coating die head specification:750mm |

| Mechanical speed (m/min) | 5~15 |

| Coating speed(m/min) | 1~12 (related to coating thickness and slurry properties) |

| Coating method | Continuous, striped, gap (gap 10mm, speed 10m/min) according to customer requirements |

| Single-sided dry film weight range | The cathode is 50~250g/㎡ |

| First-time excellent rate | ≥99% |

| Equipment failure rate | ≤1.0% |

| GR&R capabilities | ≤10% |

| Coating roll accuracy | O.D. TOLERANCE (mm): ±0.02

Cylindricity (mm): 0.002 Radial runout (um): <1.5 Levelness (mm/m): 0.05 Straightness (um): ≤1.5 |

| Roll passing accuracy | O.D. TOLERANCE (mm):±0.1

Cylindricity (mm): 0.05 Radial runout (um): <30 Levelness (mm/m): 0.1 Straightness (um): ≤30 |

| Rubber roller (pressure roller) accuracy | O.D. TOLERANCE (mm): ±0.1

Cylindricity (mm): 0.1 Radial runout (um): <30 Levelness (mm/m): 0.2 Straightness (um): ≤30 |

| Over the roll and over the roll | Parallelism (mm): 0.05 |

| Passing through the roller room in the oven | Parallelism (mm): 0.1 |

| Over rollers and rubber rollers | Parallelism (mm): 0.2 |

(3) Total configuration list:

| No. | The name of the unit | Qty | Brand | Remark |

| 1 | Unwinding unit | 1 | Unwinding manual single-shaft mechanism, manual reel changing and splicing, 3-inch air shaft feeding; | |

| 2 | Coating unit | 1 | Extrusion coating; | |

| 3 | Slurry conveying unit | 1 | precision screw feeding; | |

| 4 | Oven unit | 1 | The total length is 16 meters, all active drag rollers; | |

| 5 | Traction unit | 1 | Closed-loop tension control; Servo drive | |

| 6 | Areal density detection | 1 | ẞ-Ray areal density detection single frame | |

| 7 | Winding unit | 1 | Manual roll change; | |

| 8 | Slurry conveying unit | 1 | Motor mixing, independent mobile feeding car; | |

| 9 | Guiding unit | 1 | deviation correction device; Steel platform ; Controller; transition rollers; | |

| 10 | Control unit | 1 | Informatization requirements: be able to generate coating process data records, such as coating temperature/coating time/coating speed/electricity consumption; (Provided by the buyer of the MES system) |

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.