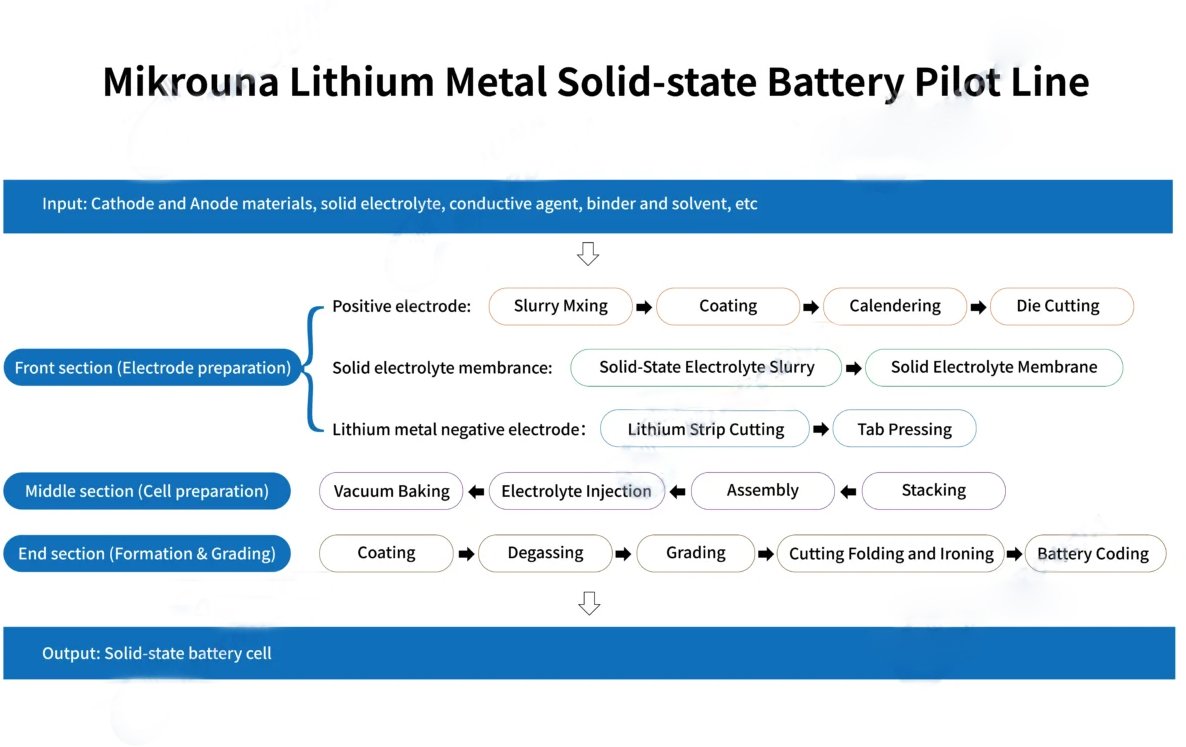

Lithium Metal Solid-state Battery Equipment Pilot Line

Designed for cutting-edge research and development in solid-state battery technology. Our glove boxes maintain H2O and O2 levels below 1PPM, ensuring safety and stability throughout the battery manufacturing process in the SSB pilot line.

The Mikrouna Solid-State Battery Pilot Line employs advanced dry and wet processes to ensure the high-performance manufacturing and stability of solid-state batteries.

Additionally, our SSB pilot line is fully customizable, making it ideal for supporting batteries with different material systems, including lithium metal anode, Polymer, oxide, and sulfide solid-state batteries.

Main sections:

– Preparation of Solid Electrolyte Materials: Precise weighing & proportioning, vacuum stirring;

– Preparation of Electrolyte Membranes: 3D printing molding / extrusion coating, roll pressing;

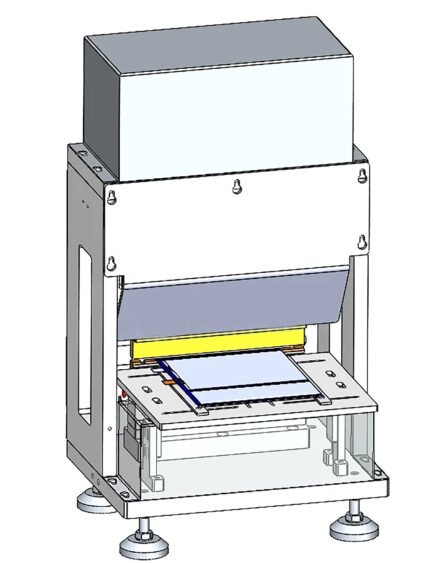

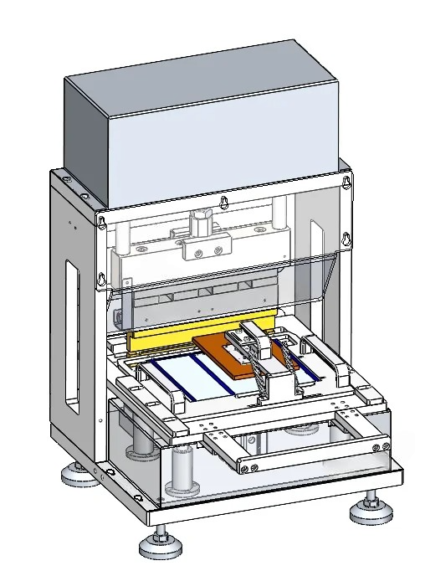

– Preparation of Electrode Sheets: Coating & baking, die-cutting & shaping, pressing copper tabs onto lithium foil;

– Assembly of Solid-State Batteries: Semi-automatic stacking, hot pressing test, ultrasonic welding, top & side sealing, vacuum electrolyte filling & sealing.

Integrating Lithium metal electrode preparation, stacking, welding, packaging, insulation

detection, vacuum electrolyte injection, and sealing functions;

The transition chamber also has a vacuum baking function;

Water and oxygen content atmosphere for the Lithium metal solid state battery line inside the glove boxes are controlled below 1ppm.

Designed for cutting-edge research and development in solid-state battery technology. Our glove boxes maintain H2O and O2 levels below 1PPM, ensuring safety and stability throughout the battery manufacturing process in the SSB pilot line.

The Mikrouna Solid-State Battery Pilot Line employs advanced dry and wet processes to ensure the high performance manufacturing and stability of solid-state batteries.

Additionally, our SSB pilot line is fully customizable, making it ideal for supporting batteries with different material systems, including lithium metal anode, Polymer, oxide, and sulfide solid-state batteries.

Main sections:

– Preparation of Solid Electrolyte Materials: Precise weighing & proportioning, vacuum stirring;

– Preparation of Electrolyte Membranes: 3D printing molding / extrusion coating, roll pressing;

– Preparation of Electrode Sheets: Coating & baking, die-cutting & shaping, pressing copper tabs onto lithium foil;

– Assembly of Solid-State Batteries: Semi-automatic stacking, hot pressing test, ultrasonic welding, top & side sealing, vacuum electrolyte filling & sealing.

Energy-saving atmosphere protection system, Material weighing proportion, Vacuum stirring, Coating and baking & 3D printing forming, Rolling Electrode cutting, Lithium foil pressing copper tab, Electrode die cutting and shaping, Lithium metal semi-automatic stacking, Hot press testing, Tab ultrasonic welding, Top-side sealing, Vacuum electrolyte injection, Vacuum sealing, Aluminum-plastic film manual forming (outside the glove box)

It provides a complete set of solutions for lithium metal battery research and development experiments, including lithium metal preparation, lithium metal negative electrode forming and a series of test equipment support.

Lithium Metal Solid State Battery Equipment Line:

Integrating Lithium metal electrode preparation, stacking, welding, packaging, insulation

detection, vacuum electrolyte injection and sealing functions;

The transition chamber also has a vacuum baking function;

Water and oxygen content atmosphere for the Lithium metal solid state battery line inside the glove boxes are controlled below 1ppm.

The Mikrouna Lithium Metal Solid State Battery Line Turnkey Solution is built in the vacuum glove boxes with following optional battery manufacturing processes:

Energy-saving atmosphere protection system; Material weighing proportion; Vacuum stirring; Coating and baking & 3D printing forming; Rolling; Electrode cutting; Lithium foil pressing copper tab; Electrode die cutting and shaping; Lithium metal semi-automatic stacking; Hot press testing; Tab ultrasonic welding; Top-side sealing; Vacuum electrolyte injection; Vacuum sealing; Aluminum-plastic film manual forming (outside the glove box)

FAQ

Q:Do you provide after-sales service?

A:Yes, our engineers available to service machinery overseas.

Q: What quotation to use?

A:General FOB quotation, other quotations can also be negotiated.

Q: In case of FOB quotation, the factory is responsible for which port to ship to?

A:Shenzhen Port.

Q:Full set of lithium battery equipment, for example:

A:Mixing machine-coating machine-rolling machine-slitting machine-stacking machine-Die cutting machine-welding machine–packaging machine –injection machine–degas machine, etc.

Q:If I want to customize the equipment, how long does it take?

A:We can provide customized services for our customers. It usually takes about 90-120 days, depending on the specifications of the customized equipment.

Q:Are you a manufacturing factory or trading company?

A:We have 3 modern manufacturing factories in Shanghai, Hubei and Dongguan of China.

Q:How to buy?

A:Simply contact our sales and inform your demands, request for a Proforma Invoice. The order will be shipped after receipt of all payment.

Q:How can I trust you?

A:Always warmly welcome for visiting our factory. Or have video call. Or arrange any of your friend to come and help you check our factory. Or any other good idea you can feel free to inform. We will do our best to cooperate. We are serious supplier in this industry for a long time. You can always rely on us.

Q:How is your warranty?

A:12 months trouble-free warranty from the date of acceptance of the equipment, during which the supplier is responsible for free remote guidance maintenance equipment. For the parts that need to be replaced during the warranty period, the transportation cost is paid by the buyer before delivery.

Q:How is your technical support?

A:Online technical support is provided free of charge during the warranty period, and offline technical support is chargeable.

Reviews

Clear filtersThere are no reviews yet.