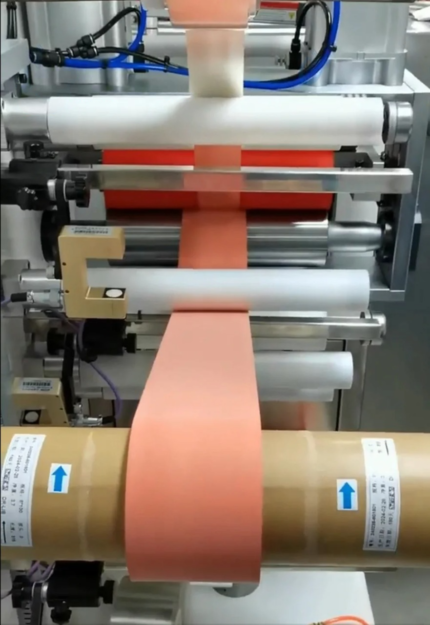

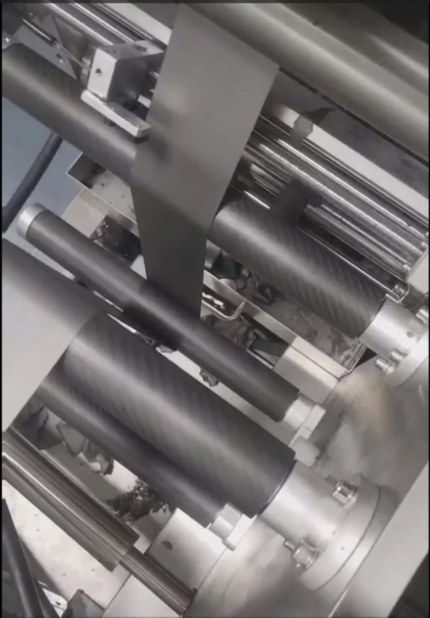

Lithium Metal Extrusion Machine for Lithium Metal Anode Preparation

sed for the lithium metal extrusion process from lithium metal ingot to lithium metal anode strips/foils, the process actions are controlled by a PLC controller and can realize inching and semi-auto operation modes.

Key parameters:

Lithium strip winding uniformity <0.5mm

After lamination, the alignment between the lithium tape and the release film is ±0.5mm

Lithium strip thickness: 0.10~3mm; thickness error ±1%

Easily adjust lithium belt width (30-110mm) and thickness (0.1-3mm)

Equipment environment: 20~23±2℃ / dew point – 45℃ or below

The width of the extruded lithium strip can reach 500mm and the thickness can reach 0.05mm (subject to the order contract);

Stable and reliable extrusion speed; uniform strip width and thickness, flat and smooth surface;

Microcomputer control of automatic extrusion, HMI display, and fault self-checking;

With a compact structure, it is used for extruding metal lithium strips and tapes.

Key parameters:

Lithium strip winding uniformity <0.5mm

After lamination, the alignment between the lithium tape and the release film is ±0.5mm

Lithium strip thickness: 0.10~3mm; thickness error ±1%

Easily adjust lithium belt width (30-110mm) and thickness (0.1-3mm)

Equipment environment: 20~23±2℃ / dew point – 45℃ or below

Reviews

Clear filtersThere are no reviews yet.