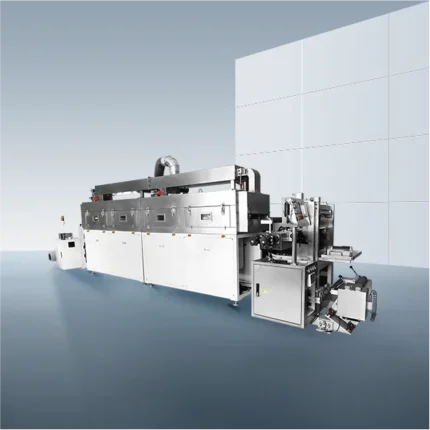

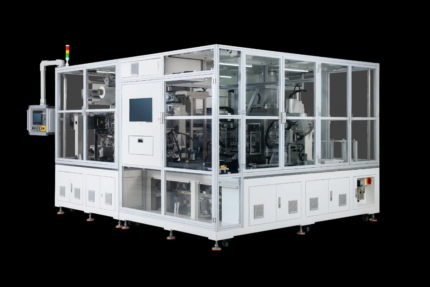

Lithium Metal Battery Automatic Stacking Machine

Product Parameters

| Item | 250 type |

| Compatible pole sheet size | L 150-250mm

M 80-200mm |

| Compatible with cell thickness | 5-20mm |

| The efficiency of single chip | ≤1s/PCS |

| End loss time | ≤8s |

| Pole piece positioning mode | CCD |

| Alignment of pole sheet to separator | ≤±0.3mm |

| Alignment of adjacent polar plates | ≤±0.2mm |

| Overall alignment of polar plates | ≤±0.4mm |

| Dust removal way | The top of the equipment is equipped with FFU, and the internal cleanliness of the equipment can reach 100,000 level after dust removal by light industrial vacuum cleaner |

| The CCD detects the alignment of the pole plate of the stack | option |

| Qualification rate | 99.2% |

| Action | 98% |

| Item | 350 Type |

| Electrode location mode | CCD visual positioning |

| Single piece efficiency | 0.5-1S/PCS |

| Compatible electrode size | L200-350mm L120-350mm |

| Stacking table structure | Cam press claw |

| Ultrasonic & missing Angle detection | Standard |

| Alignment of adjacent electrode | ≤±0.2mm |

| Overall alignment of electrode | ≤±0.4mm |

| Alignment between the electrode and the adjacent separator |

≤±0.4mm |

| Separator cut-off and reverse closure time | ≤12S |

| Dusting mode | The top of the equipment is equipped with FFU to remove dust |

| Separator electrostatic removal | Standard |

| MES function | It can dock with MES system |

| Item | 450 Type |

| Electrode location mode | CCD visual positioning |

| Single piece efficiency | 0.5-1S/PCS |

| Compatible electrode size | L300-600mm L80-150mm |

| Stacking table structure | Air Cylinder pressure claw |

| Ultrasonic & missing Angle detection | Standard |

| Alignment of adjacent electrode | ≤±0.3mm |

| Overall alignment of electrode | ≤±0.5mm |

| Alignment between the electrode and the adjacent separator |

≤±0.5mm |

| Separator cut-off and reverse closure time | ≤12S |

| Dusting mode | The top of the equipment is equipped with FFU to remove dust |

| Separator electrostatic removal | Standard |

| MES function | It can dock with MES system |

| Item | 600 Type |

| Electrode location mode | CCD visual positioning |

| Single piece efficiency | 0.5-1S/PCS |

| Compatible electrode size | L450-600mm L80-150mm |

| Stacking table structure | Air Cylinder pressure claw |

| Ultrasonic & missing Angle detection | Standard |

| Alignment of adjacent electrode | ≤±0.3mm |

| Overall alignment of electrode | ≤±0.5mm |

| Alignment between the electrode and the adjacent separator |

≤±0.5mm |

| Separator cut-off and reverse closure time | ≤12S |

| Dusting mode | The top of the equipment is equipped with FFU to remove dust |

| Separator electrostatic removal | Standard |

| MES function | It can dock with MES system |

| Item | Semi-auto Type |

| Outer diameter of separator material roller | <Φ200mm |

| Inner diameter of material roller | 3″ |

| Width of separator material | 50-300mm |

| Thickness of separator material | 0.02-0.04mm |

| Stacking speed | 4~6 seconds / sheet (positive / negative electrode) |

| Active unwinding of separator | Working tension 10N~30N adjustable |

| Separator stacking accuracy | Cell thickness 5-20 ≤ ±0.3mm (end to end homogeneity) |

| Electrode sheet stacking accuracy | Cell thickness 5-20 ≤ ±0.3mm (central deviation value) |

| Combination accuracy of separator and electrode sheet | Cell thickness 5-20 ± 0.3 mm (central deviation value) |

| Equipment running rate | 95% |

| Product qualified rate | 98% |

| Product Details | |

| Mechanical arm for taking electrode | 1.Precise, high speed and stable operation between the trough and the stacking table.

2.Taking and discharge material in vacuum is stable and reliable , it equipped with vacuum meter to detect vacuum degree. Vacuum meter can be set and adjusted according to actual needs, and has the function of recording and taking materials. |

| Separator unwinding, correction, tension mechanism | 1.The separator tension is controlled by the floating roller and the low friction cylinder to make the separator tension keep constant and the battery tension uniform and consistent.

2.Separator can automatically correct. |

| Cathode electrode storage box

|

1.The cathode electrode is a single tank configuration, which can put multiple layers of sheet material.

2.Automatic stop alarm when there is no material in the trough. Manually replace the trough. |

| Anode electrode table

|

Put the anode electrode single sheet material box on the table. The material box is positioned by the dowel pin, accurate and reliable.

|

| Positioning mechanism

|

1.The single piece of cathode and anode electrode is precisely positioned to ensure the alignment accuracy between each layer of the cell.

2.Because of the material characteristics of the anode electrode, the material box is manually switched. 3.With missing electrode detection and prompt function. |

| Stacking mechanism

|

1.Pneumatic circuit is used to control the action of each claw, and servo motor drives the stacking table to adapt to different layers of cells. The pressure of the claw can be adjusted by the precision pressure regulating valve.

2.The servo electric drive is used to make it move in high speed, accurate and stable between the positive and negative electrode taking mechanical arms. 3.Four independent cylinders drive the press claw to make X-Y bi-directional compound movement, press and position the pole plate and separator, and realize the Z-shaped lamination assembly process of the positive and negative electrode plate and separator to form the battery cell. |

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.