Lithium Metal and Copper Foil Rolling Composite Machine for Lithium Metal Battery Anode

Welcome to explore our cutting-edge Lithium and Copper Foil Rolling Composite Machine, specifically engineered for the production of solid-state battery anodes. This machine represents a pivotal advancement in battery manufacturing technology, combining precision engineering with state-of-the-art materials processing to deliver unparalleled performance and reliability.

Introduction

Welcome to explore our cutting-edge Lithium and Copper Foil Rolling Composite Machine, specifically engineered for the production of solid-state battery anodes. This machine represents a pivotal advancement in battery manufacturing technology, combining precision engineering with state-of-the-art materials processing to deliver unparalleled performance and reliability.

Lithium-Copper Composite Tape Process Overview

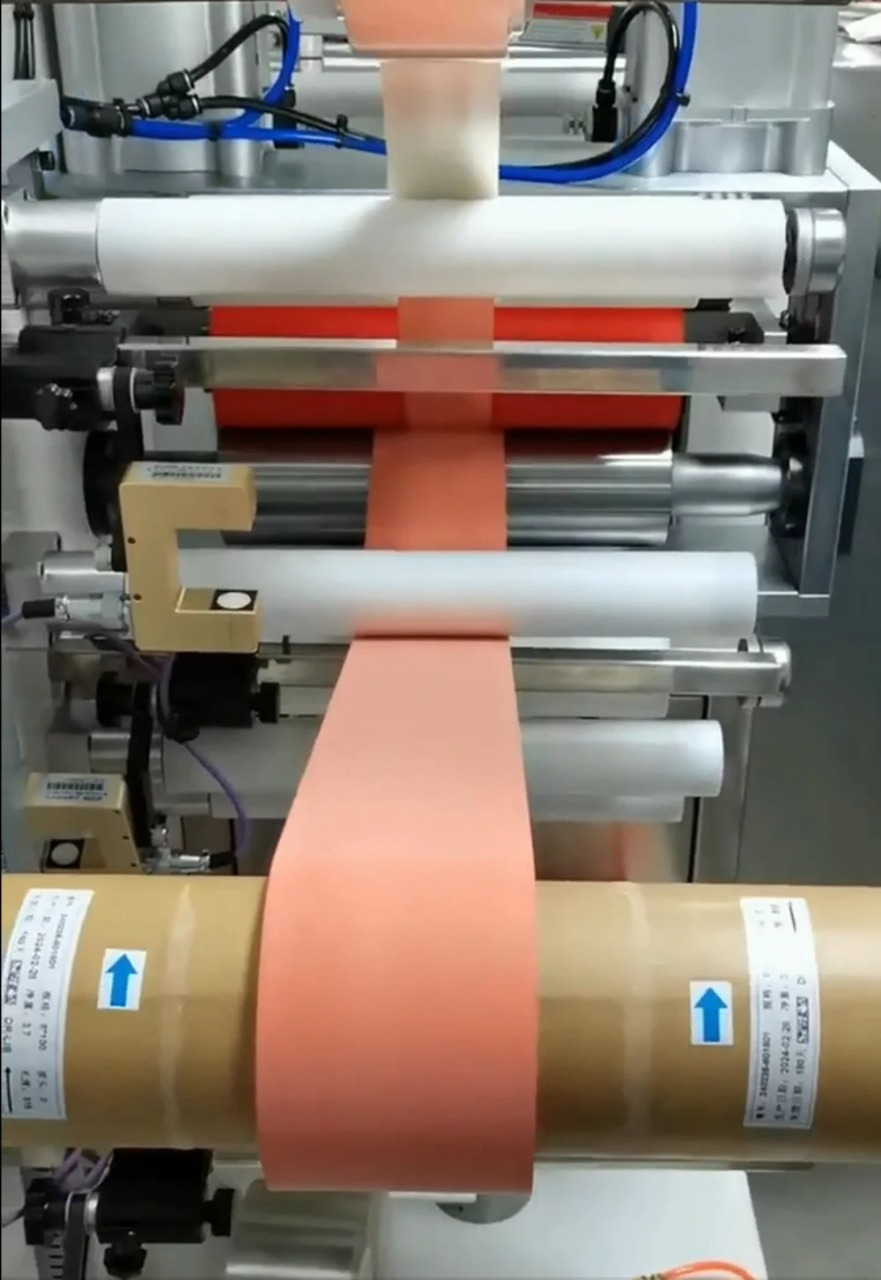

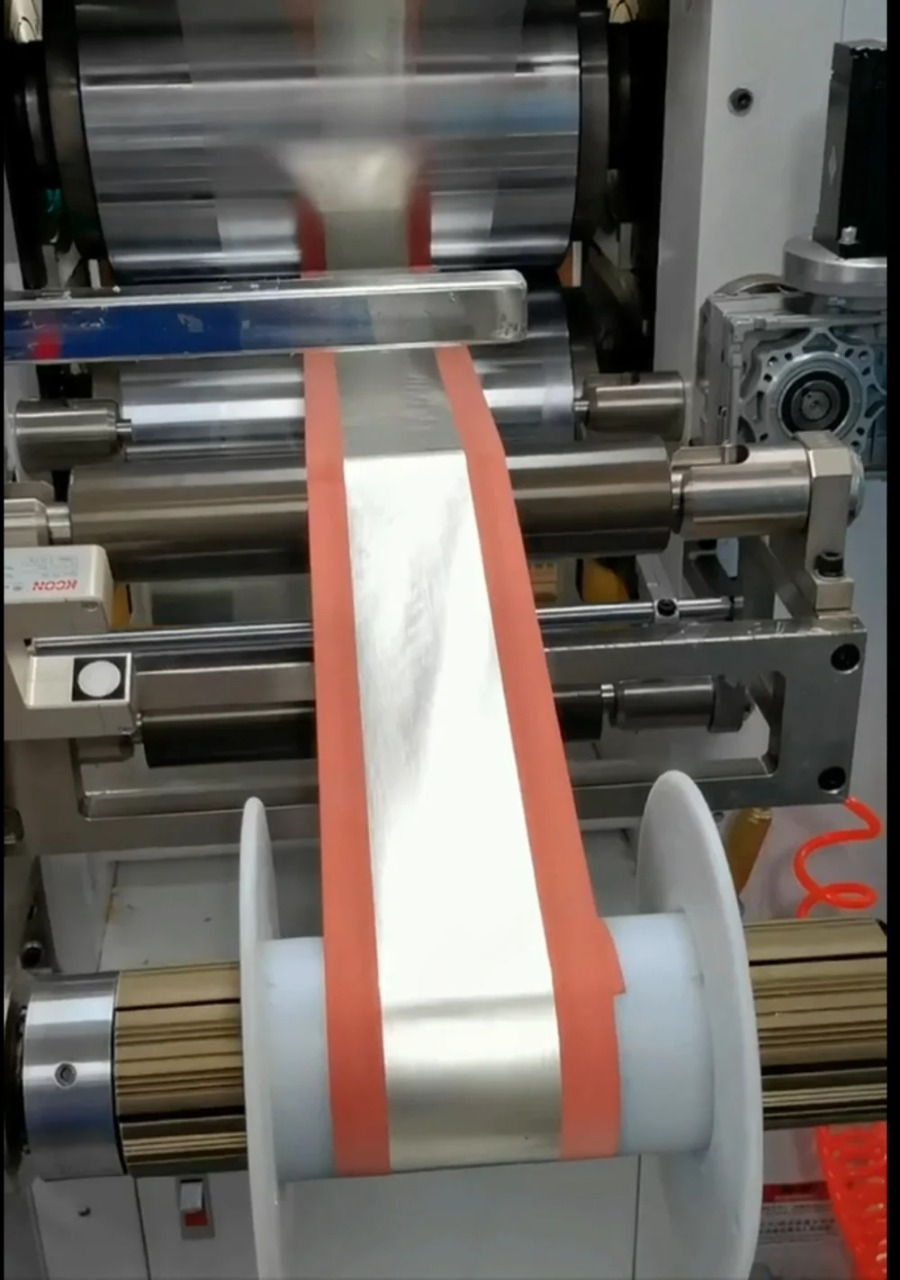

The Lithium and Copper Foil Rolling Composite Machine employs an innovative process that bonds lithium strips and copper foil to create a robust, high-performance anode material for solid-state batteries. The process begins with the preparation of lithium strips and copper foil, which are then fed into the machine. Through a series of meticulously designed steps, including stripping, flattening, laminating, and winding, the machine produces a seamless composite tape that meets the stringent requirements of solid-state battery manufacturing.

Specifications

1. Material Specifications:

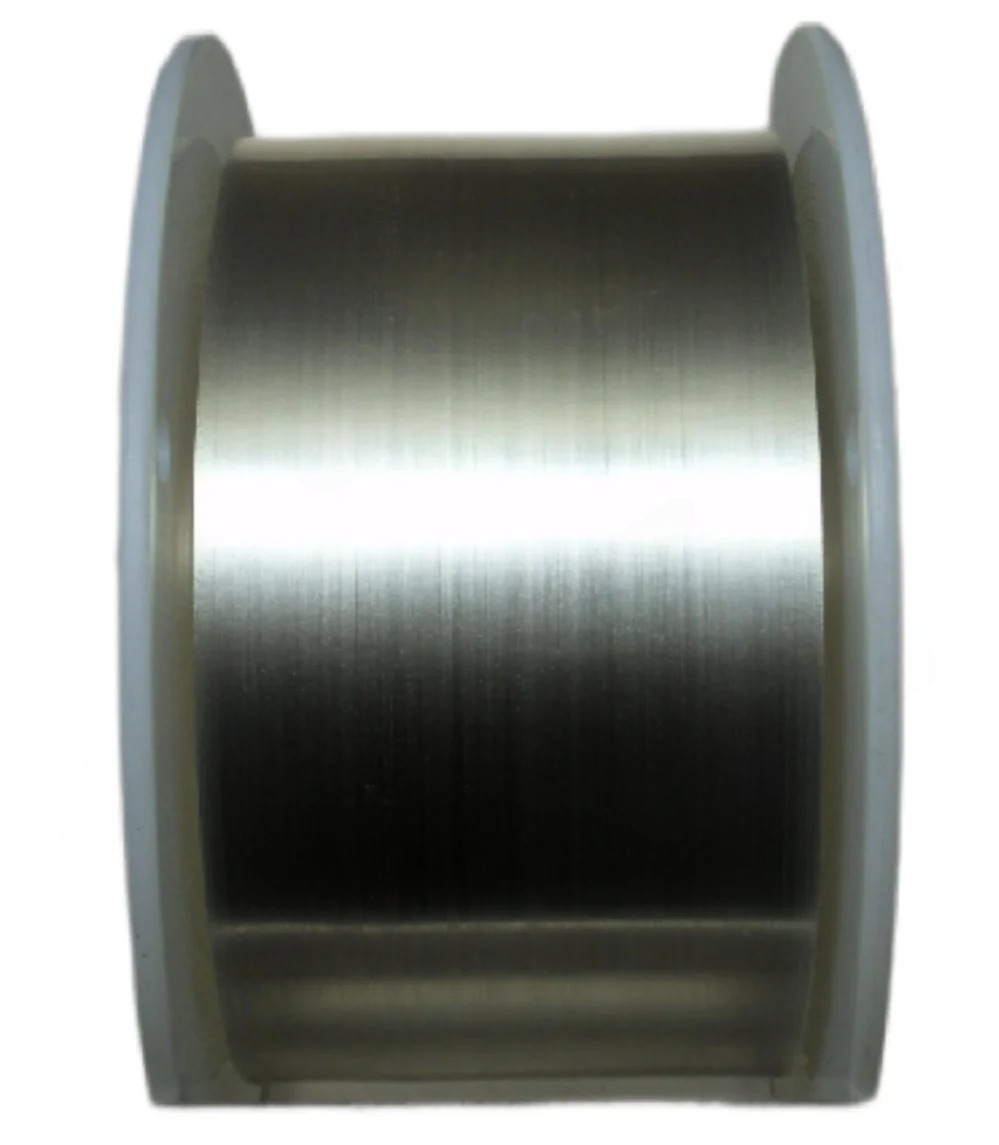

Lithium Strips: Width ≤ 200mm, thickness between 30μm and 50μm, outer diameter of rolled material ≥ ¢350mm, weight > 8kg.

Copper Film: Width ≤ 240mm, thickness ≤ (6 ~ 10) μm, outer diameter of copper roll material ≤ ¢300mm, weight after winding ≥ 20kg.

2. Laminating Capabilities:

Capable of single and double-sided laminating with copper foil.

The product surface remains wrinkle-free and defect-free after lamination.

Alignment accuracy of lithium strips and copper foil edges: < ±1mm.

Ductility in width direction: ≈ 5.0-6.0%.

3. Double-Sided Wrapping:

When double-sided copper foil is wrapped, a PP film is used as a protective layer between each layer.

Product winding length > 1000m.

4. Acceptance Blueprint:

Lithium strips with a thickness of 20μm and a width of 130mm can achieve single and double-sided lamination with copper foil.

Winding length > 500m.

Equipment Technical Parameters

1. Material Handling:

The incoming lithium strip is coated with PP film. A stripping and flattening roller device ensures separation from the PP film before lamination.

The separated PP film is wound separately by the winding mechanism.

2. Production Speed:

The entire machine operates at a speed ranging from 3m/min to 30m/min.

3. Laminating Mechanism:

Features an independent PP film unwinding mechanism for double-sided lithium coating on copper foil strips.

PP film is used as a protective layer between layers of laminating tape.

4. Tension Control:

Equipped with a comprehensive automatic control system for winding tension.

Ensures material tension control to prevent stretching during winding.

5. Precision Unwinding:

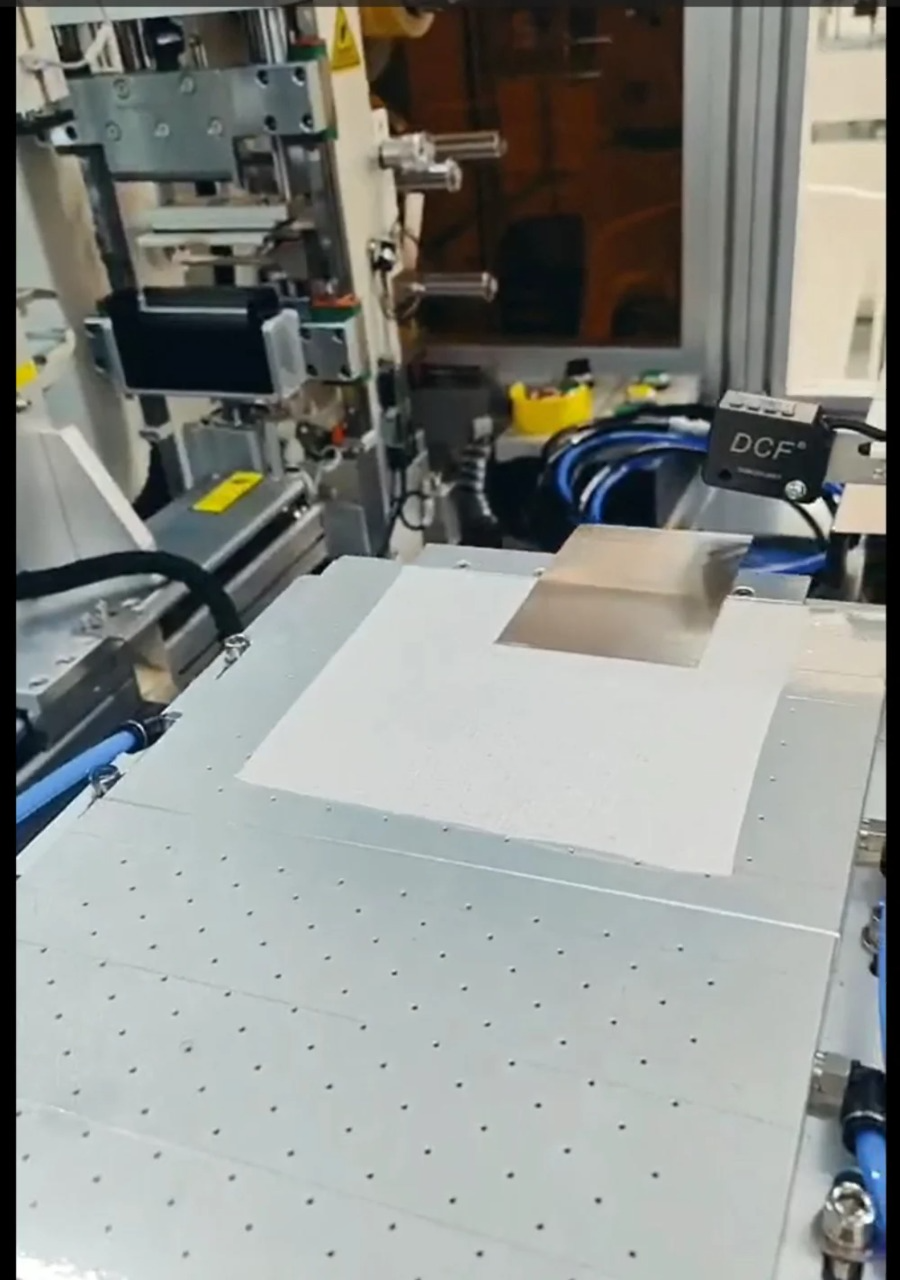

Active unwinding mechanisms and automatic deviation correction systems for incoming material, PET film, copper foil, and PP film.

Deviation correction accuracy: ±0.2mm.

6. Static Electricity Removal:

The release film PET (PP) winding and unwinding mechanism is equipped with a static electricity removal device.

7. Winding Compatibility:

Meets winding requirements for both 3-inch cores (outer diameter 350mm) and inner hole ¢20 reels.

8. Pressure and Adjustment:

Maximum lithium-copper cladding pressure: 10T (single side 5T).

Servo-automatic adjustment with digital display of clearance and pressure.

9. Laminating Roller:

Achieves differential and same-speed operation.

Cumulative error (including runout, parallelism, assembly errors) ≤ 3μm.

Roller surface smooth, free of cracks, indentations, spots, scratches, etc.

Roller body hardness > HRC65, surface coating hardness > HRC75.

10. Copper Foil Surface Treatment:

Equipped with a copper foil corona generator to meet process requirements.

Additional Specifications

1. Equipment Capacity:

Design speed ≥ 25m/min, acceptance speed ≥ 10m/min (lithium tape must be ≥ 8m/min when overlaid onto copper tape).

2. Failure Rate: ≤ 5.0%.

3. First-Time Optimization Rate: ≥ 98% (only if damage is caused by the equipment itself).

4. Power Supply: 380V three-phase five-wire system.

5. Energy Consumption: 15KW.

6. Appearance Color: Based on the buyer’s provided color palette.

7. Noise: ≤ 75dB (measured at 1000mm from the outer wall of the equipment).

8. Load-Bearing Ratio: ≤ 500Kg/m² (under full operating conditions).

9. Usage Environment:

23 ± 3 ℃, RH ≤ 1% or dew point ≤ – 45 ℃ or above.

Conclusion

Our Lithium and Copper Foil Rolling Composite Machine represents a significant leap forward in solid-state battery anode production. With its precision engineering, state-of-the-art materials processing, and robust technical specifications, this machine is poised to revolutionize the battery manufacturing industry. Contact us today to learn more about how our machine can enhance your production capabilities and drive innovation in solid-state battery technology.

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.