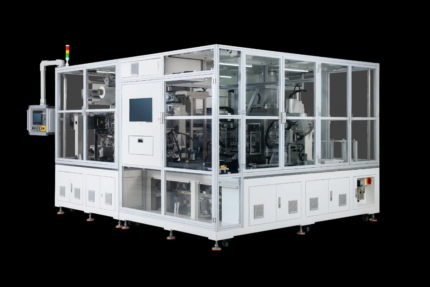

Lithium Battery Automation Pilot/Production Line in Glove Boxes

This battery automation line in glove boxes can fully automate the production of lithium batteries, greatly improving Pouch cell (vacuum electrolyte filling) production efficiency and saving labor costs.

We are also building a new sample line for this automation line in our Dongguan, Guangdong factory right now.

Lithium Battery Automation Pilot/Production Line in Glove Boxes:

This battery automation line in glove boxes can achieve fully automated production of lithium batteries. Greatly improves production efficiency and saves labor costs.

We are also building a new sample line for this automation line in our Dongguan, Guangdong factory right now.

Below are the working steps for this line:

Step 1: Battery raw materials enter the glove box from the feeding bin;

Step 2: Battery raw material packages are automatically scanned and weighed;

The weighed battery raw material packages are automatically placed on the material conveyor.

Step 3: The conveyor automatically enters the electrolyte injection cylinder for filling;

Step 4: The filled batteries enter static cylinders 1, 2, 3 for resting;

Step 5: After resting, the batteries enter the sealing cylinder for vacuuming and sealing;

Step 6: The sealed batteries are automatically weighed again;

Unqualified products will enter the recycling transition bin on the left for processing.

Step 7: Qualified batteries will be automatically sent to the material outlet module.

The entire battery production process can be automated.

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.