Glove Box Installation and Commissioning

Installation and commissioning item preparation list

For the glove box you ordered, please prepare the following items required for installation and commissioning:

1. Two bottles of pure argon gas(or nitrogen) with a purity of 99.99%.

2. One bottle of high-purity argon gas(or nitrogen) with a purity of 99.999%.

3. One bottle of argon-hydrogen (or nitrogen-hydrogen) mixed gas.

The hydrogen content is 5% to 10% (recommended to be 8% for the best effect), and the rest is high-purity argon gas(or high-purity nitrogen gas).

The inert gas used for items 1, 2 and 3 should be the same!

4. One pressure reducing valve for gas cylinders.

The main gauge pressure range is greater than 15 MPa, and the secondary gauge pressure range is 0 – 1 MPa (or can accurately read 0.4 – 0.6 MPa).

5. One pressure reducing valve for gas cylinders.

The main gauge pressure range is greater than 15 MPa, and the secondary gauge pressure range is 0 – 0.5 MPa (or can accurately read 0.05 – 0.08 MPa).

The thread interface of the pressure reducing valve is consistent with that of the argon-hydrogen mixed gas cylinder.

Gas and other criteria required by the system

| Working Gas | Nitrogen, Argon or Helium |

| Purity | 99.999% |

|

Quantity |

Ensure a continuous supply (generally, during the initial installation, it is necessary to purge and replace the air in the box. Each section of chamber requires approxi- mately 4000-8000 liters (standard volume) of gas). |

| Regulator | Primary valve pressure range>150bar ( 15MPa) [ >2,200 psi ]

Second valve pressure range 0~10bar ( 0-1MPa) [ 0-150 psi ] |

|

Regenerating Gas |

Depending on applications:

When Nitrogen is the working gas, use Nitrogen/Hydrogen mixture (90-95% N2, 5-10% H2) When Argon is the working gas, use Argon/Hydrogen mixture (90-95% Ar ,5-10% H2) When Helium is the working gas, use Helium/Hydrogen mixture (90-95% He, 5-10%H2) |

| Purity | 99.999% |

| Regulator | Each regeneration process for MK100 purifier needs approx. 3,000 – 4,000 L [125 –

150 cu. ft.] (Measured at standard atmospheric pressure) of gas mixture |

| Purging Gas | Use the same gas as the working gas (Share one gas source) |

| Purity | 99.99% or above |

| Quantity | When purging the glove box illed with atmospheric air, each single workstation glove box needs 4000-8000L [150 – 300 cu. ft.] (Standard Atmosphere Pressure) working gas.

For initial purging, >8000L [>300 cu. ft.] working gas is recommended |

| Regulator | Primary valve pressure range>150bar (15MPa) [>2,200 psi] Second valve pressure range 0~10bar (0-1MPa) [0 – 150 psi] |

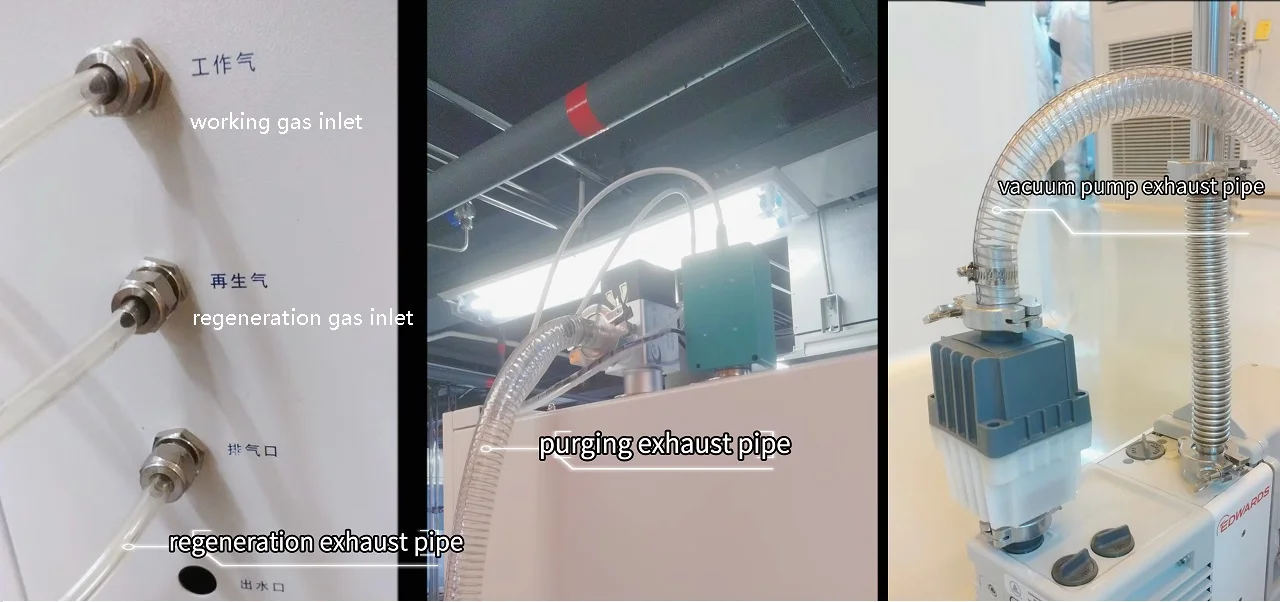

Gas connection guide

Gas inlet: ruffles( sleeve coupling ), outer diameter 8 mm.

Regeneration exhaust: ruffles( sleeve coupling ), outer diameter 8 mm.

Purging exhaust: outer diameter 25 mm, connected to the hose.

Vacuum pump exhaust: outer diameter 25 mm, connected to the hose.

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.