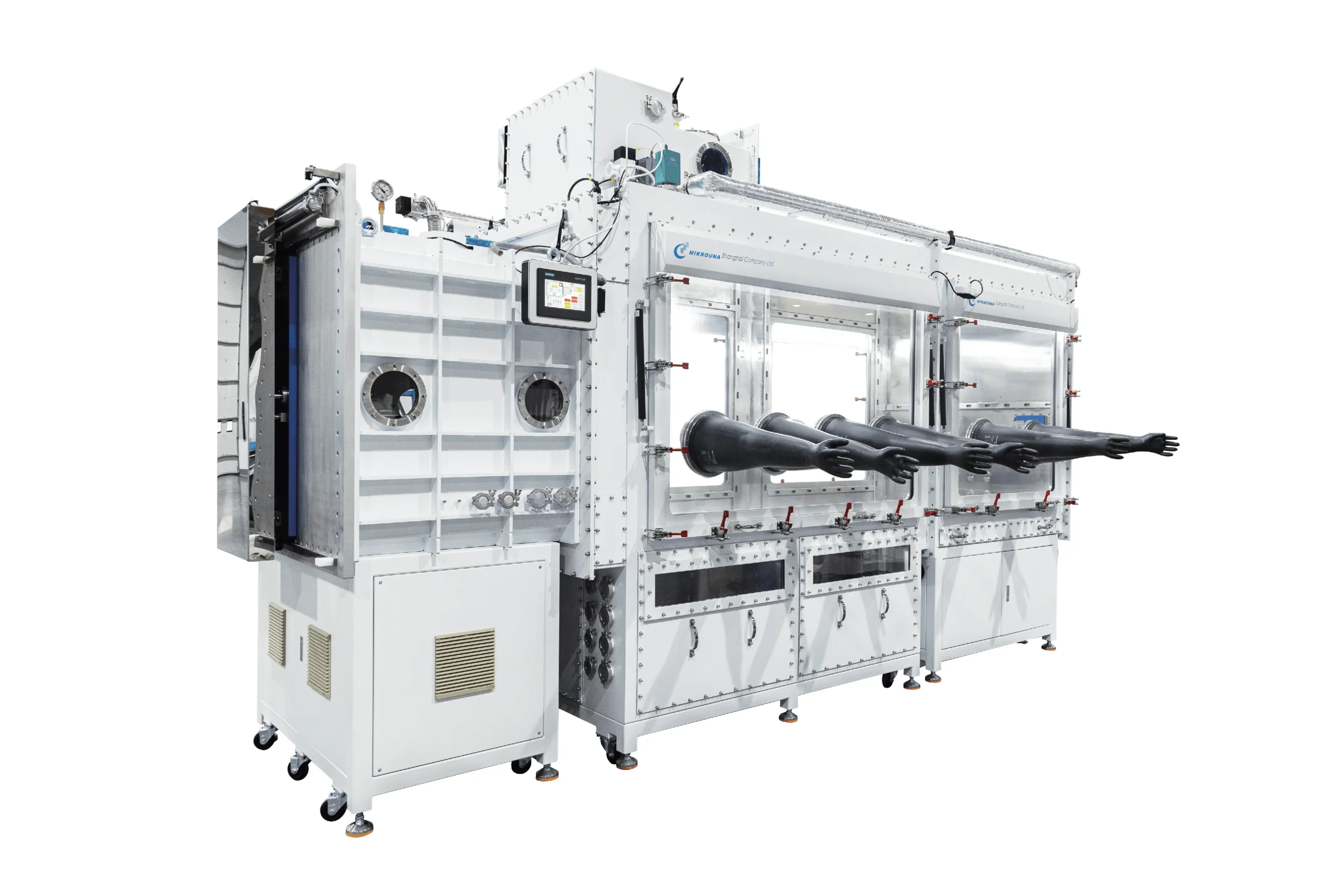

Custom Glove Box Solutions

Mikrouna Customized Glove Boxes are modular, high-end containment systems designed for precision operations in controlled environments.

Developed by Mikrouna since 2004, these gloveboxes integrate advanced gas purification, IoT-enabled automation, and multi-industry adaptability, serving as foundational platforms for specialized research and industrial processes

Mikrouna Customized Glove Box Overview

Part I Core Features

1. IoT Intelligence

Real-time monitoring of internal pressure, temperature, humidity, and gas purity, with remote smartphone control (e.g., parameter adjustment, lighting control).

Smart maintenance alerts: Automatic notifications for molecular sieve/activated carbon replacement, pump oil cleaning, etc., sent directly to user terminals.

2. Modular Architecture

Customizable modules:

✔️ Inert gas purification system (O₂/H₂O <0.1 ppm)

✔️ Vacuum transfer locks (compatible with MBE/ALD equipment)

✔️ Explosion-proof electrical components (ATEX Zone 2 certified)

3. Multi-Industry Applications

| Industry | Typical Applications |

|---|---|

| New Energy | Li-metal solid-state battery assembly, dry-room integration for sodium-ion electrodes |

| Nuclear Industry | Nuclear fuel handling, radioactive waste containment (leaded viewport + triple HEPA) |

| Advanced Manufacturing | Aerospace-grade metal 3D printing, OLED evaporation encapsulation (Class 100 cleanroom) |

4. Certifications

ISO 9001 quality management, CE/UL electrical safety certifications, approved supplier for China National Nuclear Corporation.

5. Technical Advantages

– Industrial Durability: Chamber constructed from 316L stainless steel/HASTELLOY® alloys, resistant to highly corrosive media.

– Scalable Flexibility: Supports dual-sided multi-station configurations (e.g., Six Stations Dual Sides) and double-layer independent gas chambers.

Part II After-Sales Service

Global network of 20+ service centers offering rapid response for installation, calibration, and lifetime maintenance.

Note: All systems support non-standard customization; specific process parameters are required for design optimization.

Part III Equipment Listings for Custom Glovebox Systems(Optimized for Global Industrial & Research Applications)

1. Organic Chemistry Experiment Glove Box

▫️ Equipment Overview

Advanced inert-atmosphere containment system designed for air-sensitive synthesis, catalyst handling, and solvent recovery.

▫️ Equipment Details

Gas Purification: <0.1 ppm O₂/H₂O via 3-stage molecular sieve

Integrated Features:

✔️ Solvent trap with 20L capacity

✔️ Cryogenic cooling unit (-40°C)

✔️ Thermal annealing oven (200°C max)

Compliance: ISO 14644-1 Class 3

2. Perovskite R&D Glove Box

▫️ Equipment Overview

Ultra-low O₂/H₂O environment (<1 ppm) for perovskite film deposition and solar cell assembly.

▫️ Equipment Details

Anti-static workspace with UV-filtered viewport

Integrated Interfaces:

✔️ Spin coater mounting plate

✔️ Evaporation source feedthroughs (4 ports)

✔️ ALD/MBE system synchronization

3. Six Stations Glove Box (Dual Sides)

▫️ Equipment Overview

High-throughput workstation for parallel operations in material science and electronics.

▫️ Equipment Details

Dual-sided access with 6 glove ports (HEPA-filtered)

Modular Zones:

✔️ Wet chemistry area (chemical-resistant coating)

✔️ Dry processing zone (0.1 ppm O₂)

Dimensions: 2000×1500×1800 mm

4. Laser Melting & Cladding Glove Box

▫️ Equipment Overview

Controlled argon environment for additive manufacturing and surface modification.

▫️ Equipment Details

Laser Compatibility: Fiber/YAG/CO₂ lasers

Gas Control:

✔️ O₂ <10 ppm, H₂O <5 ppm

✔️ Argon recirculation (99.999% purity)

Safety: Explosion-proof electricals

5. Double-Layer Glove Box

▫️ Equipment Overview

Dual-chamber system for multi-step processes requiring separate atmospheres.

▫️ Equipment Details

Independent Zones:

✔️ Outer chamber: <5 ppm O₂

✔️ Inner chamber: <0.5 ppm O₂

Transfer Airlock: 300×300 mm pass-through

6. Nuclear Application Glove Box

▫️ Equipment Overview

Radiation-shielded containment for nuclear fuel handling and waste processing.

▫️ Equipment Details

Shielding: 50mm leaded borosilicate glass viewport

Safety Systems:

✔️ Triple HEPA filtration (99.999% @0.3μm)

✔️ Master-slave manipulator interfaces

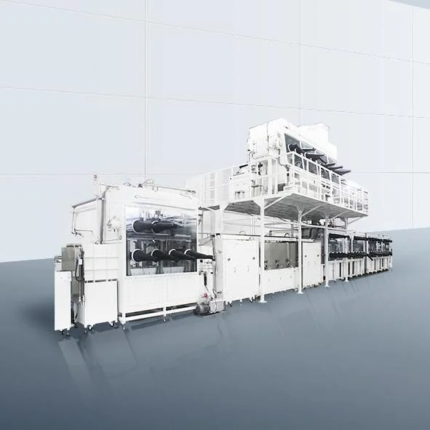

7. Lithium Battery Series

| Product Name | Equipment Overview | Equipment Details |

|---|---|---|

| Solid-State Battery Line | Fully automated production for Li-metal anode assembly | ✔️ AI-driven defect detection ✔️ 50-cell/hour throughput |

| Sodium-Ion Production Line | Closed-loop dry room integration for Na-ion cathodes | ✔️ 0.5% RH control ✔️ 300-cycle/day capacity |

| Battery R&D Glove Box | Solvent-recovery system for electrode slurry mixing | ✔️ Explosion-proof design ✔️ 12 glove ports |

8. OLED Manufacturing Glove Box

▫️ Equipment Overview

Class 100 clean environment for organic vapor deposition and device encapsulation.

▫️ Equipment Details

Particulate Control: <0.01 μm particles

Integrated Tools:

✔️ Multi-zone heating (20-150°C ±1°C)

✔️ 12″ wafer loadlock with robotic arm

9. 3D Printing Glove Box Series

▫️ Equipment Overview

ISO Class 4 environment for aerospace-grade metal powder handling (Ti-6Al-4V, Inconel 718).

▫️ Equipment Details

Build Volume Options: 800×800×1200 mm / 1200×600×600 mm

Gas Control: O₂ <30 ppm (powder feeding), <50 ppm (laying powder)

10. Vacuum Film Coating All-in-One

▫️ Equipment Overview

Integrated evaporation coating and glovebox system for perovskite/OLED device fabrication.

▫️ Equipment Details

Vacuum Chamber: 10⁻⁶ Pa base pressure

Transfer System: Inert-atmosphere sample transfer

Compatibility: 150mm wafer handling

11. Customization Service

▫️ Modular Options

Materials: 316L stainless steel / HASTELLOY®

Gloves: Butyl/Viton®/Hypalon® (12-18 mil thickness)

Gas Systems: MB/PSA/VSA purification

▫️ Compliance

✔️ ASME BPE ✔️ ATEX Zone 2 ✔️ CE/UL certification

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.