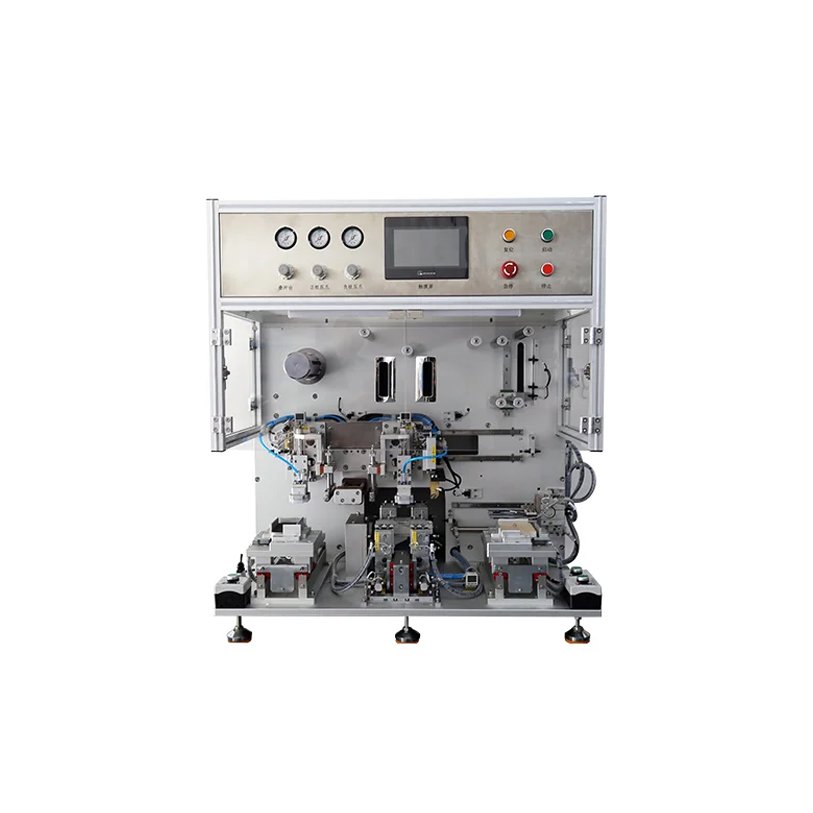

Battery Electrode Sheet Stacking Machine

The lithium negative electrode adopts single-layer sheet material box to switch manually as the feeding and positioning table, and the material box and the positioning table adopt pin positioning to move to the feeding position (the lithium negative electrode sheet material box is completed by another process); at the same time, it can be compatible with the configuration of graphite and silicon carbon negative electrode material box of the secondary batteries (multi-layer sheet material).

Product features

(1). The lithium negative electrode adopts single-layer sheet material box to switch manually as the feeding and positioning table, and the material box and the positioning table adopt pin positioning to move to the feeding position (the lithium negative electrode sheet material box is completed by another process); at the same time, it can be compatible with the configuration of graphite and silicon carbon negative electrode material box of the secondary batteries (multi-layer sheet material);

(2). Positive electrode picking up mechanical arm mechanism adopts vacuum picking up of electrode sheet in positive electrode trough;

(3). Positive and negative electrode pieces are alternately discharged on the stacking table; the stacking table moves back and forth between servo-driven robotic arms to match the action, so that the isolation film forms a Z-shape to separate the positive and negative electrode pieces; the equipment is so cyclic to realize the stacking assembly of the electrode group, the stacking table is driven by servo motors to lift and lower the table, and when the number of the stacked pieces reaches the set value, the servo manipulator for transferring the battery core sends the electrode group to the (reserved length of the coiled separator) cutting knife to cut. separator, complete the stacking function

(4). Collect the electric core manually by hand, and close and glue the separator manually.

(5). Lithium metal can be stacked, the whole set of equipment placed in the drying room operation

Applicable battery cell specification range

Lithium metal negative electrode/Z type stacking/naked cell

Battery cell dimensions:

| Item | Name | Size (mm) | Remarks |

| H | Length H | 100~300 | |

| W | Width W | 50~150 | |

| T | Thickness T | 5-15 | |

| P | Tab exposed length P | ≤30 |

Material parameters of equipment processing:

| Item | Content |

| 1 | Separator thickness T1 (unit: mm): 0.02≤T1≤0.04 |

| 2 | Positive electrode thickness T2 (unit: mm): 0.05≤T1≤0.25 |

| 3 | Negative electrode thickness T3 (unit: mm): 0.01≤T1≤0.25 |

| 4 | Negative electrode thickness (lithium metal) T4 (unit: mm): 0.01≤T1≤0.25 |

| 5 | Electrode sheet length A (unit: mm): 100≤L≤300 |

| 6 | Electrode sheet width B (in mm): 50≤L≤150 |

| Equipment Process Parameters | Specifications |

| Outer diameter of separator material roller | <Φ200mm |

| Inner diameter of material roller | 3″ |

| Width of separator material | 50-300mm |

| Thickness of separator material | 0.02-0.04mm |

| Stacking speed | 4~6 seconds / sheet (positive / negative electrode) |

| Active unwinding of separator | Working tension 10N~30N adjustable |

| Separator stacking accuracy | Cell thickness 5-20 ≤ ±0.3mm (end to end homogeneity) |

| Electrode sheet stacking accuracy | Cell thickness 5-20 ≤ ±0.3mm (central deviation value) |

| Combination accuracy of separator and electrode sheet | Cell thickness 5-20 ± 0.3 mm (central deviation value) |

| Equipment running rate | 95% |

| Product qualified rate | 98% |

| Equipment Installation Requirements | Specifications |

| Overall dimensions | L*W*H=1080*950*1060mm |

| Temperature range | 18℃ ~ 25℃ at room temperature |

| Compressed air | 0.6 Mpa, 10 L/min |

| Vacuum source | Vacuum degree -60 Kpa (customer-provided) |

| Installation power | 1kW |

Product pictures

Schematic diagram of the semi-automatic stacking equipment:

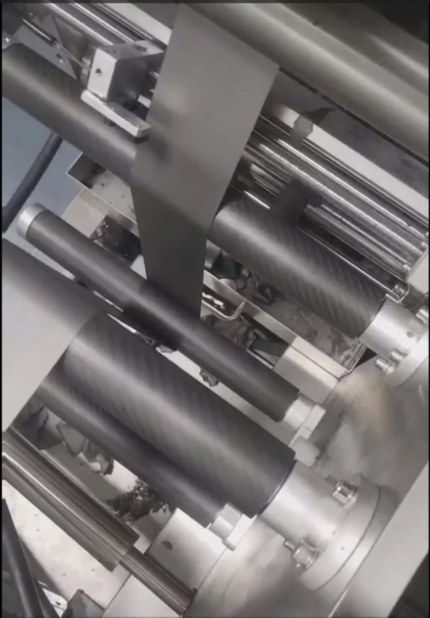

Electrode sheet storage tank: (positive electrode)

Electrode table: (lithium negative form)

Locating mechanism:

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.