Blog

How CowinLink Energy is Revolutionizing Battery Manufacturing with Automation

Revolutionizing Battery Manufacturing with Automation

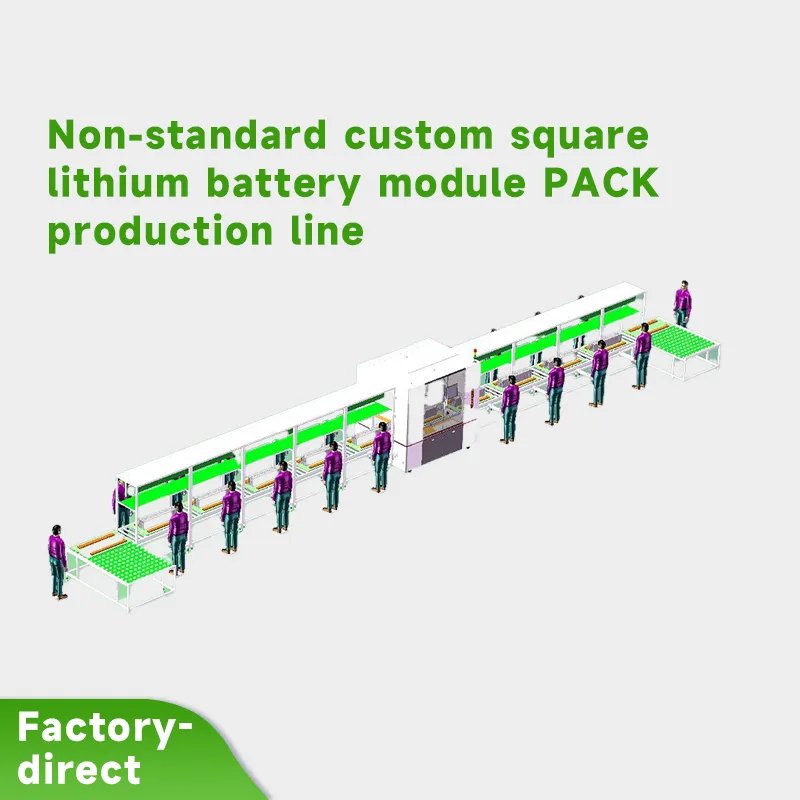

Battery production demands precision, consistency, and efficiency, and CowinLink Energy is at the forefront of innovation with its fully automated and semi-automated production lines. Our state-of-the-art machinery streamlines battery assembly, testing, and quality control, ensuring high-speed, high-accuracy manufacturing.

Innovative Technologies Driving Efficiency

To enhance productivity and reliability, we integrate:

- Laser Welding Technology – Provides precise and durable battery connections, ensuring structural integrity and performance.

- AI-Driven Quality Inspection – Uses advanced algorithms to detect and correct defects, maintaining optimal battery performance.

- Automated Sorting & Grading Machines – Enhances efficiency and accuracy by categorizing battery cells based on voltage, internal resistance, and capacity.

Setting New Industry Standards

By embracing automation and smart manufacturing, CowinLink Energy is redefining the future of battery production. Our approach delivers:

- Faster Production Cycles – Accelerating output while maintaining quality.

- Enhanced Workplace Safety – Reducing human intervention in hazardous processes.

- Greater Reliability & Consistency – Minimizing errors and maximizing efficiency.

As the demand for energy storage solutions grows, CowinLink Energy continues to push the boundaries of battery manufacturing technology, ensuring a smarter, safer, and more sustainable future.