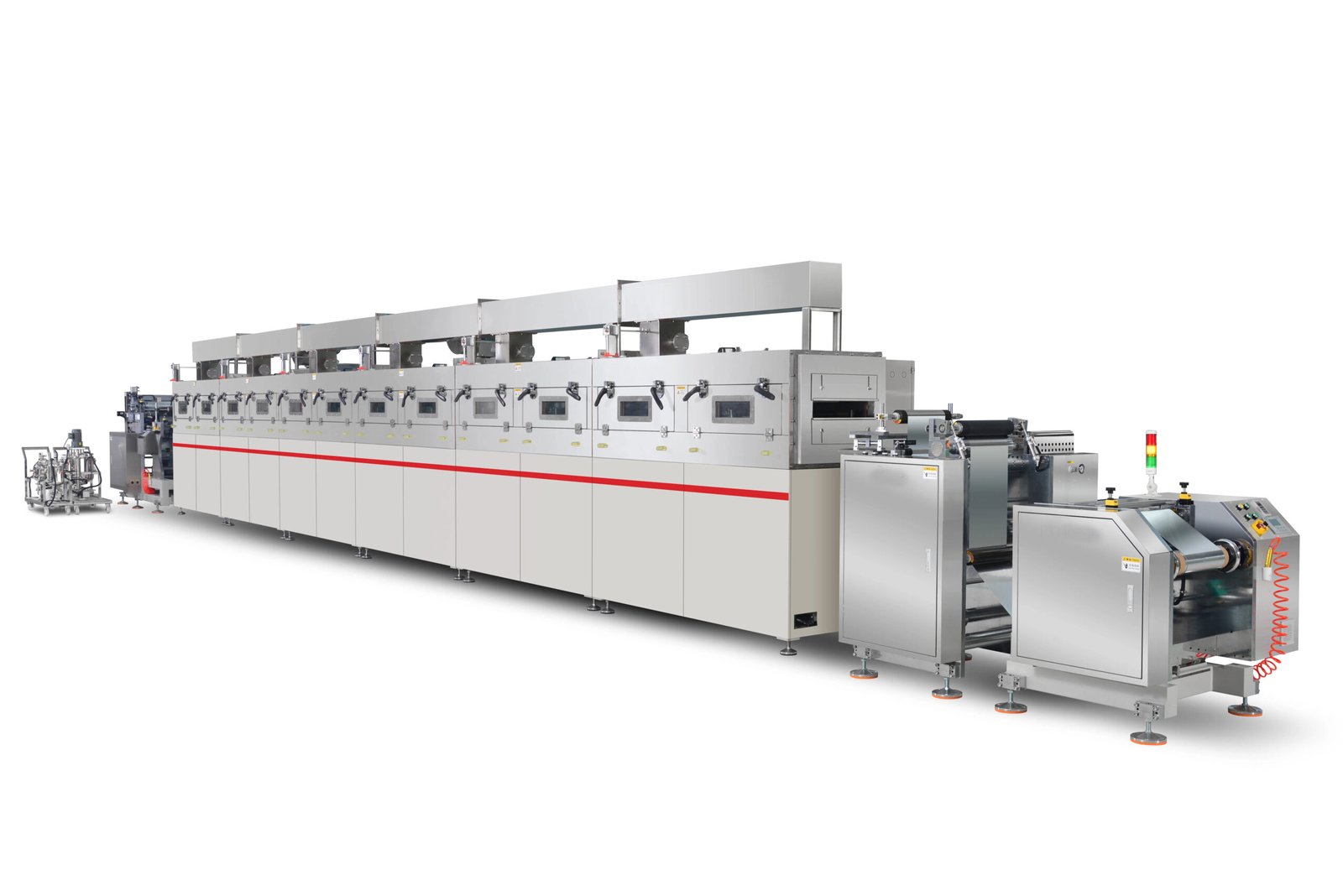

Multi-type Battery Electrode Coating Machine with Multi-mode (Extrusion, Transfer, Micro-gravure)

This equipment is utilized for the precise coating of lithium-ion battery cathode and anode electrodes. It offers versatile coating modes, including slot die, transfer, and micro-gravure, which are interchangeable and compatible.

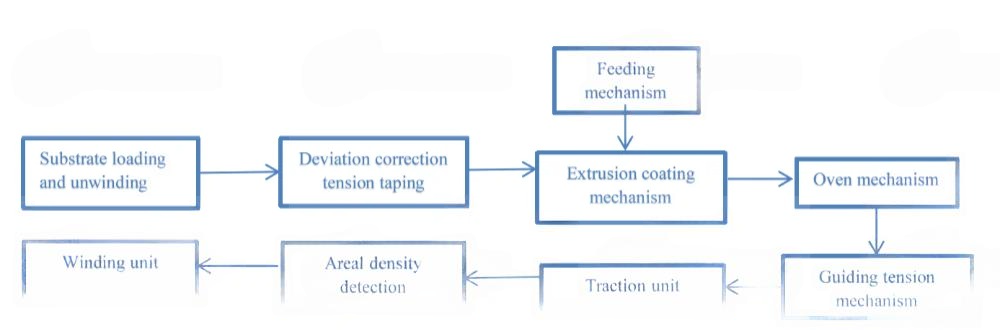

The machine primarily comprises an unwinding unit, extrusion coating head, transfer coating head, micro-gravure coating head, slot die feed system, micro-gravure feed system, oven section, NMP recovery system, traction unit, winding unit, and electrical control system.

It uniformly applies the mixed slurry onto the substrate, ensuring that dimensions and weight meet process specifications.

This equipment is an integrated machine with diverse coating methods to cater to various coating process requirements in the lithium-ion battery industry.

Equipment Overview/Function:

This equipment is utilized for the precise coating of lithium-ion battery cathode and anode electrodes. It offers versatile coating modes, including slot die, transfer, and micro-gravure, which are interchangeable and compatible. The machine primarily comprises an unwinding unit, extrusion coating head, transfer coating head, micro-gravure coating head, slot die feed system, micro-gravure feed system, oven section, NMP recovery system, traction unit, winding unit, and electrical control system. It uniformly applies the mixed slurry onto the substrate, ensuring that dimensions and weight meet process specifications. This equipment is an integrated machine with diverse coating methods to cater to various coating process requirements in the lithium-ion battery industry.

Equipment Function and Principle Introduction:

The three-in-one coating machine for large-diameter gap coating on both sides of lithium-ion battery electrodes consists of an unwinding unit, web guiding and tension control unit, front and back coating units, drying unit, and winding unit. It uniformly coats the mixed slurry onto the substrate, ensuring that dimensions and weight fall within design specifications. After drying, the coated material is wound up, preparing it for subsequent manufacturing processes.

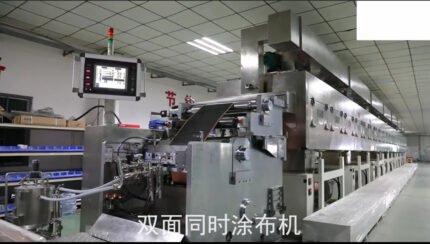

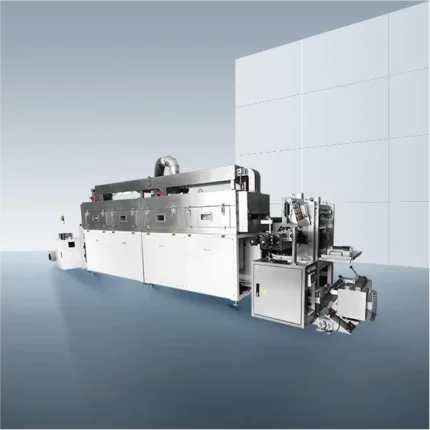

Equipment Appearance, Dimensions, and Weight:

Appearance:

Dimensions: Approximately L (18m) × W (2.5m) × H (2.5m) (excluding the electrical cabinet and material cart width)

Total Equipment Weight: Approximately 12 tons;

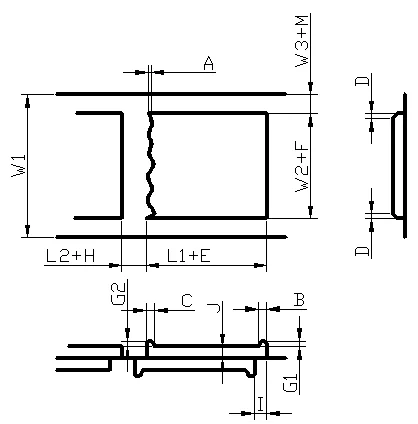

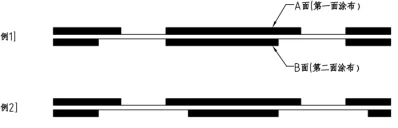

Product Accuracy for Intermittent Coating in Lithium-Ion Battery Manufacturing:

A (Tail Drag) ≤1mm (related to slurry viscosity and binder characteristics)

B (Abnormal Leading Edge Area) ≤10mm; -10~+8um

C (Abnormal Trailing Edge Area) ≤8mm; -10~+8um

D (Edge Effect Area) ≤8mm, -10~0um (measured with a 6mm diameter micrometer)

E/H (Length Variation) ≤±0.5mm

F (Width Variation) ≤±0.5mm

M (Width Variation in Tab Area) ≤±0.5mm (excluding substrate width variation ≤0.1mm)

I (Front-to-Back Alignment Error) ≤±0.5mm

Longitudinal Alignment Error for Front and Back Sides ≤±0.8mm

Single-Side Area Density Variation (excluding B, C, D areas) Weight Variation ≤±1.5%

Double-Side Area Density Variation (excluding B, C, D areas) Weight Variation ≤±1.8%

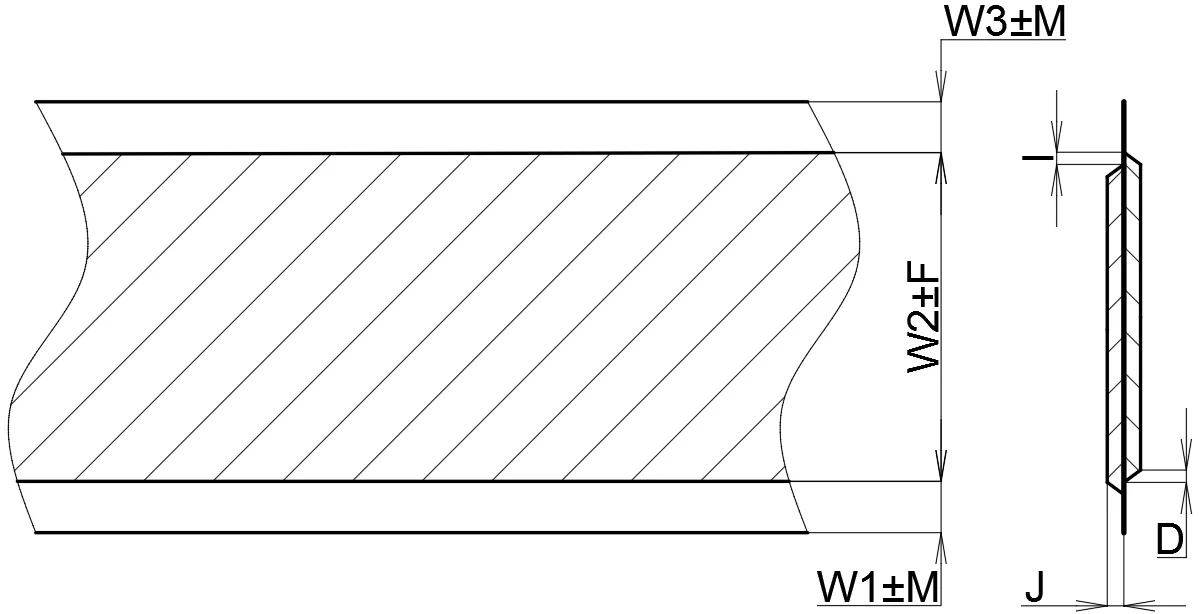

Product Accuracy for Continuous Coating in Lithium-Ion Battery Manufacturing:

D (Edge Effect Area) ≤8mm, -10~0um (measured with a 6mm diameter micrometer)

F (Width Variation in Coating Area) ±0.5mm

M (Width Variation in Edge Tab Area) ±0.5mm (excluding substrate width defects)

I (Longitudinal Alignment Error for Front and Back Sides) ≤±0.5mm

Single-Side Area Density Variation (excluding D area) Weight Variation ≤±1.5%

Double-Side Area Density Variation (excluding D area) Weight Variation ≤±1.8%

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.