Auto Electrolyte Injection Machine for Pouch Cell

The size of the Incoming Cell

| Incoming cells from the electrolyte injection machine | Cell length A | 160~290mm |

|

| Cell width B | 90~160mm | ||

| Overall cell length with battery tab C | 200~300mm | ||

| Overall width of the shell D | 170~260mm | ||

| Cell thickness T | 5~15mm |

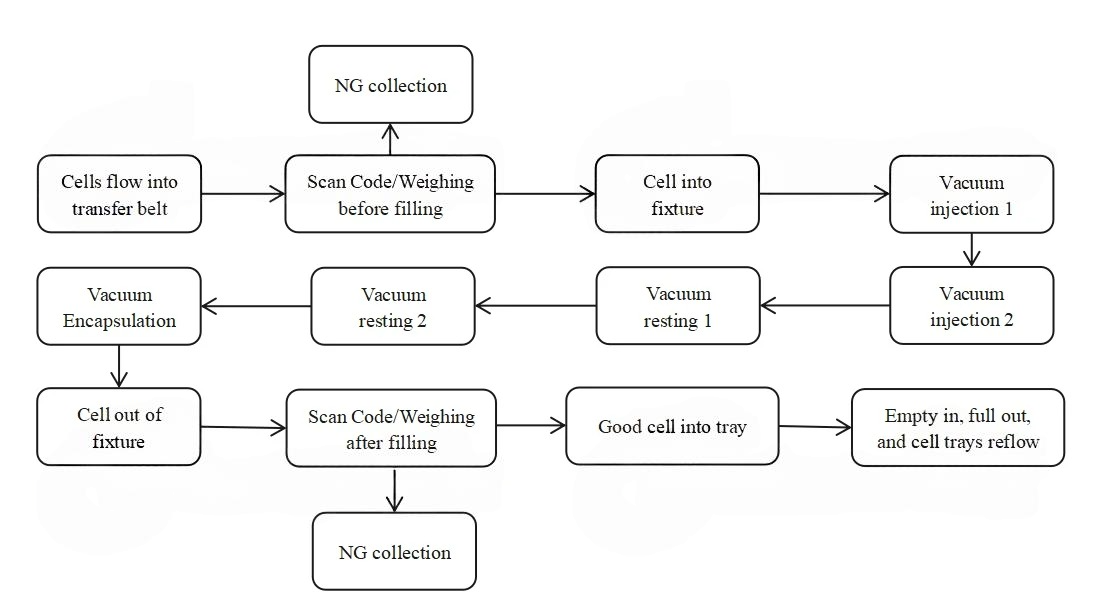

Main component structure

| NO. | Component | Illustration |

| 1 | Feeding manipulator | It has servo motor manipulator (X, Y, Z three sets), cylinder clamping, frame, etc. Complete the reclaiming, weighing and scanning code, and filling tooling. |

| 2 | Weighing and scanning mechanism | 1. Feeding weighing mechanism, one set before and after electrolyte injection; A set of code scanning mechanism before electrolyte injection;

2. After each weighing, it can request automatic clearing operation; 3. The weighing mechanism can be shockproof and corrosion-proof; 4. The weighing mechanism is equipped with a self-calibration weight; 5. The battery injection volume information is automatically transmitted to the industrial computer, and the injection amount is determined to meet the process requirements after processing; 6. Marble platform is applied, and all mechanisms are electrolyte corrosion resistant materials.

|

| 3 | Battery injection tooling and mobile devices | 1. Each set of battery clamps can place 4 batteries at the same time.

2. The battery steps through the pusher device, and moves in steps; 3. Two sets of fixtures moving up and down mechanism; 4. The fixture is refluxed to the double-speed chain, and the fixture is reflowed

|

| 4 | Vacuum injection | 1. Automatically open the air bag of the pouch cell and confirm in vacuum condition before electrolyte injection;

2. The electrolyte injection nozzle adopts a residual electrolyte connection mechanism to prevent the electrolyte dripping from polluting the battery; 3. The electrolyte level limit sensor is set on the electrolyte storage tank, and the corresponding voice-activated alarm is equipped; 4. During the electrolyte injection process, complete the functions of automatic electrolyte replenishment and vacuum bubble removal of the electrolyte storage tank.

|

| 5 | Pressurized standing under vacuum | 1. The battery of the tray after electrolyte injection is automatically transported to the automatic static standing station, the static cavity is pressed down and the equipment tray is sealed, and the beating + positive pressure + vacuum is carried out in multiple cycles, a total of 2 standing;

2. The sealed mechanical self-locking cavity structure is adopted, which can realize the positive pressure static position of the cavity; 3. Equipped with booster pump and air tank to ensure stable air pressure.

|

| 6 | Vacuum sealing | 1. Each battery corresponds to a set of heads; Limit packaging, easy maintenance and adjustment;

2. The lower cavity is easy to open, exposing the head part, which is convenient for head maintenance; 3. In order to avoid the inconsistency of the parallelism of the two heads during processing, the head adopts W-shaped design and maintenance-free function; 4. The vacuum degree of the packaging position is -80~ -95%, the temperature uniformity of the packaging head is ±2°C, and the uniformity of the packaging thickness is ≤±15um.

|

| 7 | Manipulator unloading mechanism | It has servo manipulators (three sets of X, Y, Z), cylinder clamping, racks, material boxes, etc. to complete weighing, testing, NG, and unloading actions

|

| 8 | Electrolyte supply system | 1. Equipped with a single-head electric electrolyte injection pump to work;

2. Each pump adopts an independent control system, and cooperates with a high-torque stepping motor to achieve accurate electrolyte discharge; 3. Single injection volume of electrolyte injection pump: 0-2.5g electrolyte injection accuracy±0.25%; 4. Equipped with automatic electrolyte supply system.

|

| 9 | Interactive | The touch screen is used to realize the human-machine dialogue and the monitoring of each operation |

| 10 | Control system | The PLC is used as the control core to control the action of the whole machine, the cell tray code is associated with the cell virtual code, and the information such as NG and Rework is associated and tracked through the Ethernet and MES docking |

| 11 | The whole machine fixing rack | Fangtong welding is used to make the performance of the whole machine stable during operation |

| 12 | Dust-proof cover | The outer cover is made of aluminum profile, and with the transparent acrylic protection |

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.