Auto Packaging Machine for Pouch Cell

Cell specifications

| Bare battery cells are incoming | Cell length A | 150~280mm | |

| Cell width B | 80~150mm | ||

| Cell thickness C | 5~15mm | ||

| Foil tab length D | 10~20mm | ||

| Negative tab width Q1 | 20~50mm | ||

| Width of positive tab Q2 | 20~50mm | ||

| The distance from the negative ear to the edge is N | 10~50mm | ||

| Tab center distance P | 40~100mm |

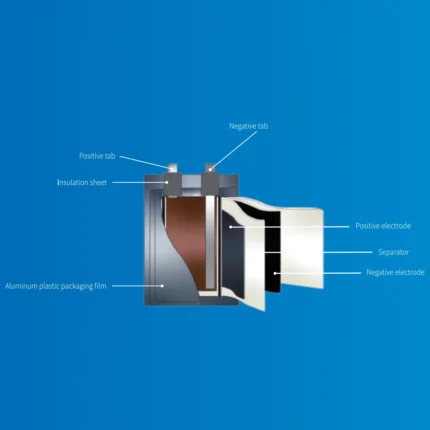

Incoming specifications of aluminum-plastic film

| Incoming aluminum-plastic film | Install the inner diameter | Φ76.5mm |

| Maximum outer diameter | Φ400mm | |

| Thickness | 0.088~0.2mm | |

| Width | 120~500mm |

PET film incoming specifications

| PET film incoming | Install the inner diameter | Φ76.2mm |

| Maximum outer diameter | Φ250mm | |

| Width | 130~320mm |

Main component mechanism

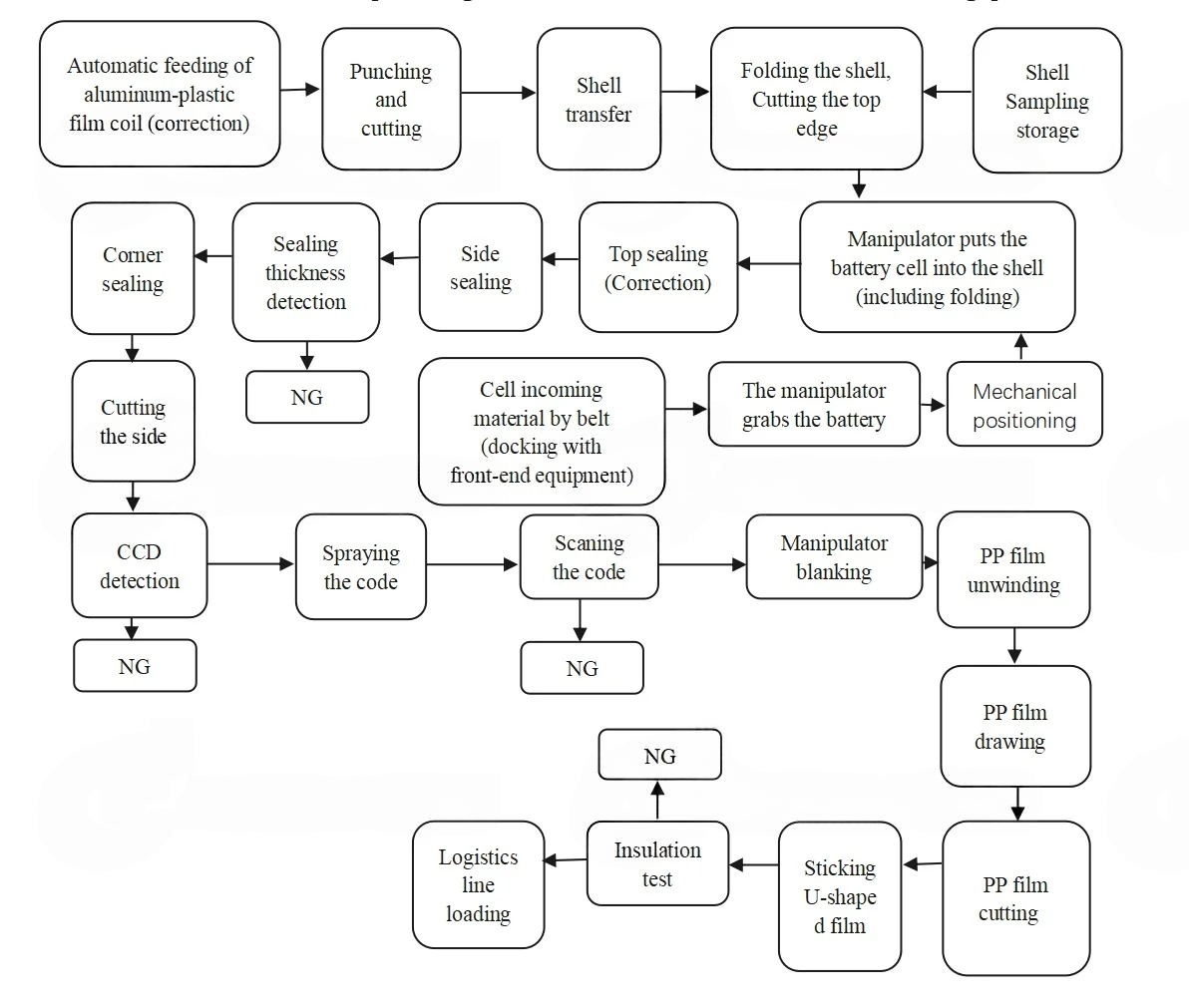

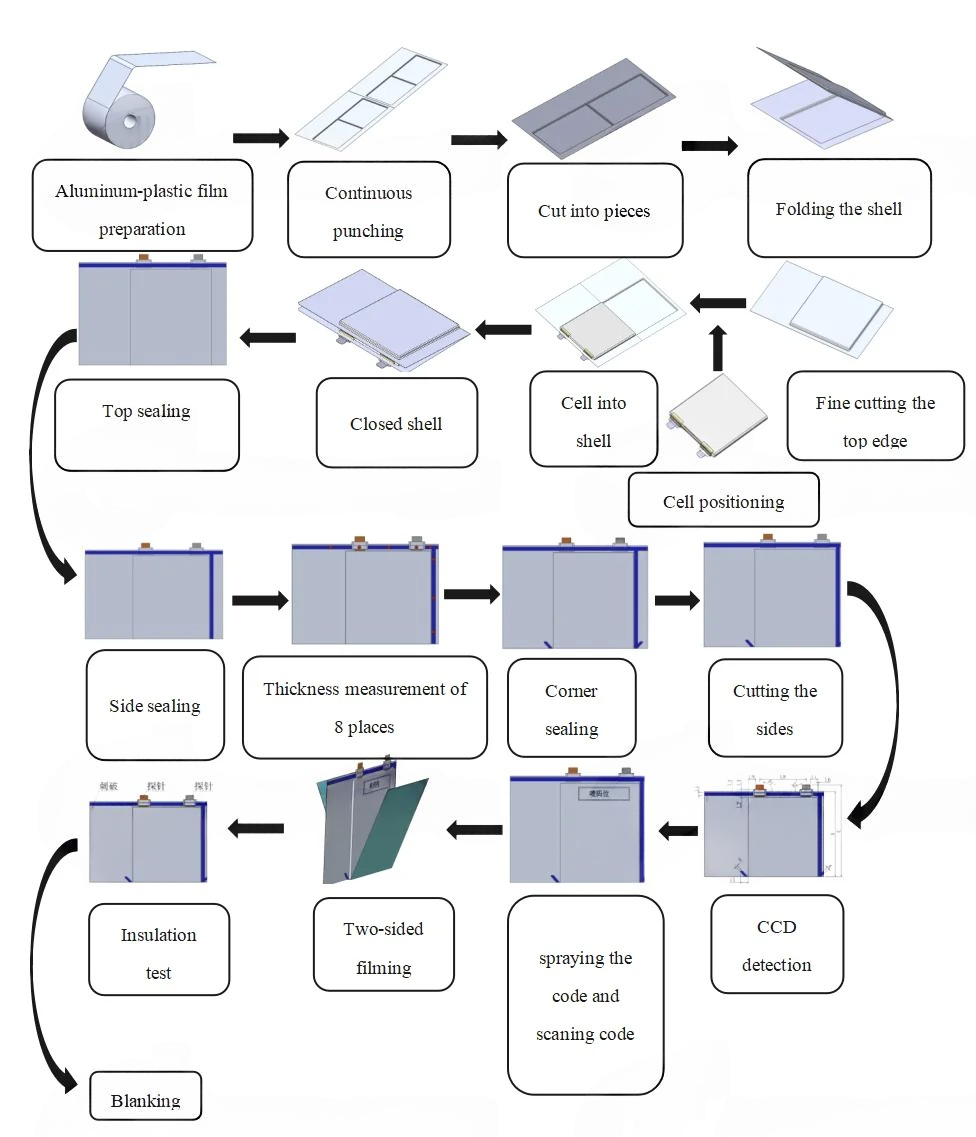

| N0. | Name of the institution | Illustrate | |

| 1 | Illustration of aluminum-plastic film molding | Action Description:

The lower template is fixed, the pressurized cylinder drives the lower mold to compress the aluminum-plastic film, and the servo mechanism forms a power drive punch to contact the aluminum-plastic film and travel (the data can be set by the touch screen), and the aluminum-plastic film is stressed to produce local deformation to achieve the shape of the designed product. |

|

| 2 | Inspection after aluminum plastic film forming |

Process sampling: Sampling for 2 to 3 hours each time to detect the deep aluminum layer and PP in key pits It is very difficult and expensive to plan the inspection equipment to the automatic line. For example, adding a light ruler to measure the depth of the pit, online scanning of PP integrity and automatic identification system, X-ray spectral recognition of the aluminum layer at a fixed point and height Note: Aluminum layer thickness detection: Micro X-ray machine: using the spectral analysis software after penetration: the thickness of the aluminum layer and the spectrum are quantified |

|

| 3 | On-line sampling mechanism for aluminum-plastic film forming shell | Action Description:

1. According to the requirements of the production process, sampling can be taken according to the time period or quantity (the data can be set on the touch screen). 2. The sampling principle of the equipment is to avoid the detection of the required position of grabbing, the shell to be tested items will not change, the collection box to be tested has a soft sponge to contact the shell, will not damage the shell. |

|

| 4 | Cutting mechanism | Before punching the shell, the stress relief slashing compensates for the stretching of the top edge of the aluminum-plastic film punching pit, and at the same time, in order to remove the foreign matter on the aluminum-plastic film before punching the pit, the methods of air blowing, vacuum dust removal and magnet are adopted. | |

| 5 | The servo motor drives the forming mechanism | Action Description:

The aluminum-plastic film is pressed under the drive of the pressurized cylinder, and the servo shell punching method realizes the shell punching function; The punching depth is controlled by servo and can be set and adjustable; Before entering the mold, there is a belt detection function, and the place where the belt is judged is not to punch the shell, and the subsequent cutting place is cut off and taken out, and the whole mold base is made of thickened steel of quenching and tempering heat treatment to ensure the strength of the mold base and prevent the mold from deformation. Advantages of the mechanism: The servo mechanism can adjust the forming speed and punch the shell with a suitable speed and constant strength, which can avoid the breaking and collapse of the aluminum-plastic film and ensure the quality and appearance of the shell. |

|

| 6 | Suction cup transfer method | ||

| 7 | Linear fixture transmission mechanism | Action flow:

1. The linear transmission mechanism has two layers of moving mechanism, lifting mechanism, so as to form a circular movement, and the upper moving mechanism moves synchronously by the servo motor guide rail to move synchronously, driving 6 groups of fixtures, and successively completing the shell, into the cell, top seal, side seal, seal thickness detection, and pull-down. The lower moving mechanism is a motor and a double-speed chain mechanism to drive the empty fixture to move. |

|

| 8 | Single-head tab cell fixture | Cell Fixture Description:

1. The manipulator folds the shell and puts it on the clamp pit plate, and a suction cup is set in the pit plate to suck the shell to prevent the shell from loosening; Then put in the battery cell. The clamp pit plate has the function of opening and closing the clamp, which is composed of a compression spring and a rack and pinion, and the station is always closed when the station is transferred. 2. Replace the upper and lower tooling to produce single-head or double-head batteries. When the battery model is changed, the upper and lower tooling needs to be replaced. |

|

| 10 | The aluminum plastic film shell is folded |

Action flow: 1. The manipulator takes the shell and puts it on the clamp pit plate, and a suction cup is set in the pit plate to absorb the shell to prevent the shell from loosening; The clamp pit plate has the function of opening and closing the clamp, and is composed of cylinder and gear rack and pinion. 2. The entry and exit mechanism drives the folding plate to extend into the tooling, after it is in place, the folding plate descends and presses the shell, the opening and closing mechanism first drives the shell to fold into a small angle, the folding plate rises and exits the tooling fixture, the opening and closing is completely closed, and the shell is folded in half. |

|

| 11 | The top edge of the aluminum-plastic film shell is cut |

Crop Mode: 1. The upper and lower cutters are driven by cylinders, and the upper and lower cutters are guided by linear slides 2. Cutter life: 1 million times (regrinding) 3. Cutter material: SKT11, quenched and tempered 4. The cutting accuracy of the top edge ±0.2mm 5. Fan vacuum waste recycling box. |

|

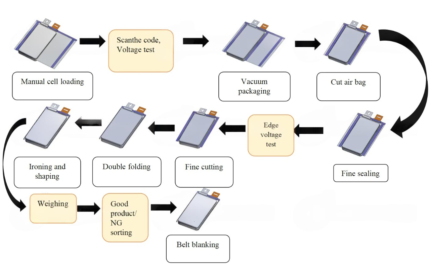

| 12 | Top side sealing mode selection |

1、The upper and lower head double servo motor drive mode: the battery cell is put into the aluminum-plastic film for thermal sealing, the lower head is stabilized by the large servo, the tab correction mechanism corrects the position of the tab, and the upper head is lowered by the small servo motor for heat sealing. (The heatsealing time and temperature can be adjusted according to the product process.) ) 2、Upper head servo motor lower head cylinder driving mode: After the battery cell is put into the aluminum-plastic film, the lower head is stabilized by the cylinder, and after the tab correction mechanism corrects the position of the tab, the upper head is lowered by a small servo motor for heat sealing. (The heat sealing time and temperature can be adjusted according to the product process.) ) |

|

| 13 | In-line inspection of sealing thickness |

Action description 1. The manipulator takes the XY direction test position. 2. The datum positioning piece is positioned under the cylinder drive. 3. Cylinder-driven thickness sensor GT2-A12K (Keyence) test, real-time transmission of test data; The inspection accuracy of the thickness gauge sensor is ± 3 μm. |

|

| 14 | Corner sealing mode |

1. Action description: The top side sealing cell sealed in the upper process is put into the tooling and then the angle position is hotly sealed, the head of the upper and lower parts moves along a common linear slide rail by the cylinder, and after the lower cylinder moves first, the small cylinder of the upper head descends for heat sealing, and there is a mechanical limit block. (Sealing pressure, time and temperature can all be adjusted according to the product process.) ) 2. Institutional parameters: Head Material: H62 Heating module: H62 + heating element + temperature sensing line Insulation: Synthetic stone Head temperature: Max 230±5°C Thickness accuracy: ±10μm Positioning accuracy of heat sealing area: ±0.2mm Package thickness control: Limit mode Packaging time: 3sec (customer process determined) Encapsulation pressure: 2.5 – 4 kgf/cm2 (compressed air barometer adjustment) |

|

| 15 | CCD video detection |

1. The packaged battery is transferred to the test platform by the manipulator for CCD video inspection. 2. It is composed of CCD camera and CCD light source, which is used to detect the size of the tab after heat sealing, and the detection and identification accuracy is ±0.05mm, and the detection content includes: tab spacing, position accuracy within ±0.1mm, position accuracy within ±0.1mm (the ear gel needs to be dark), the overall size of the cell and the tilt angle of the tab, the width of the top side seal, the position of the corner seal, etc. |

|

| 16 | Trimming |

Crop Mode: 1. The upper and lower cutters are driven by cylinders. Upper and lower cutter linear slide guides 2. Cutter life: 1 million times (regrinding) 3. Cutter material: SKT11, quenched and tempered 4. The cutting accuracy of the top edge ±0.2mm 5. Fan vacuum waste recycling box. |

|

| 17 | Inkjet printer instrument | ||

| 18 | Insulation test Instrument | ||

| 19 | Collection of defective products | ||

| 20 | Interactive | The touch screen is used to realize the human-machine dialogue and the monitoring of each operation | |

| 21 | Control system | The PLC is used as the control core to control the action of the whole machine, the cell tray code is associated with the cell virtual code, and the information such as NG and rework is associated and tracked through the Ethernet and MES docking | |

| 22 | The whole machine is fixed in a rack | Fangtong welding is used to make the performance of the whole machine stable during operation | |

| 23 | Dust-proof cover | The outer cover is made of aluminum profile, and the transparent acrylic is protected | |

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.