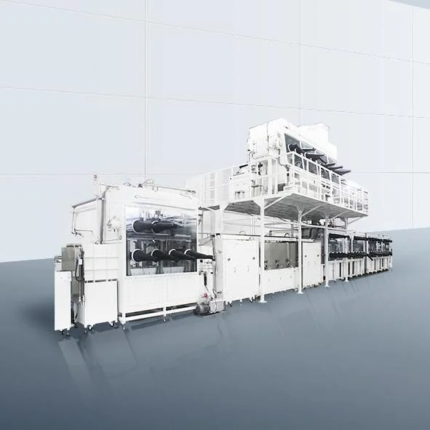

Double, Multi-station Vacuum Glove Box With Water & Oxygen Purification System For Battery Research Laboratory

Introducing Mikrouna’s Vacuum Glove Box System, specifically designed for lithium battery laboratory research and development. This innovative solution offers performance and versatility, catering to the stringent requirements of the lithium battery industry.

| Glove Box Composition | |||

| Glove box | Purification unit | ||

| Box body | Material:304 stainless steel,thickness 3mm Exterior surface:304 stainless steel (color can be customized) Inner surface:oil film drawing surface Internal dimensions:single section of different lengths 1220, 1500,1800,2440mm Different depth 750,1000,1200mm Height 900mm |

Purification column | Function:gas seal,water removal,oxygen removal

Container material:304 stainless steel Purification material:copper catalyst 5kg,molecular sieve 5kg Purification capacity:oxygen removal 60L,water removal 2kg |

| Front Window | O-ring vacuum flange seal,tempered glass thickness 8mm | Circulating system | Water and oxygen index:<1ppm Working gas:nitrogen,argon,helium Circulation capacity:integrated fan flow 90m²/h (Higher fan flow available:145m²/h,180m²/h) |

| Glove opening | Material is aluminum alloy:O-ring seal | ||

| Glove | Butyl rubber:thickness 0.4mm,diameter 7“or 8” | Regeneration | Operation:PLC automatically controls the regeneration

process |

| Filter | Specification:0.3μm,one gas inlet and one gas outlet | ||

| Supporter | Material:Stainless steel,built-in 3 layers,adjustable height | Vacuum pump | Specification:12m³/h,16m³/h

Rotary vane pump:with oil mist filter,air vibration control |

| Box lighting | Location:LED light,installed in the lampshade

Specifications:DN40KF,several standby interfaces,1 power |

||

| Interface | Valve | Main valve:DN40KF,electropneumatic angle valve Control valve:solenoid integrated valve |

|

| Circular transition bin | Circular small transition bin | Circular big transition bin | Standard rectangular transition bin | Standard rectangularsmall transition bin | Standard rectangular big transition bin |

|||

| Bin body | Size | Diameter 150mm Length 300mm |

Diameter 360mm(Optional 400mm) Length 600mm |

Bin body | Size | Size:120x150mm | Size:260x300mm

Optional:360×360mm/ 450×450mm 304 stainless steel |

|

| Materials | 304 stainless steel | 304 stainless steel | Materials | 304 stainless steel | 304 stainless steel | |||

| Surface treatment | The inner surface is the oil film drawing surface,

and the outer surface is spray-paint or mirror surface |

Surface treatment | The inner surface is the oil film drawing surface,

and the outer surface is spray-paint or mirror surface |

|||||

| Tray | Tray | Sliding Tray | Tray | With pallet, no slideway | Sliding Tray | |||

| Accessory | Bin gate | Dual doors | Dual doors,with anodized aluminum material,Thickness 10mm,vertical operation, with lift structure |

Accessory | Bin gate | Dual doors | Dual doors,with anodized aluminum material,Thickness 10mm,vertical operation, with lift structure |

|

| Pressure

meter |

Analog display | Analog display | Pressure

meter |

Analog display | Analog display | |||

| Control | Operation | Manual operation | Automatic control | Control | Operation | Manual operation | Automatic control | |

| *Upure:With internet remote control and automatic antechamber door. | ||||||||

| Model Parameters | ||||

| Model | Super/Upure | Universal | Advanced | |

| Operation surface Dimensions L*W*H (mm) | Single station (Single side) |

1220x750x900 | 1220x750x900 | |

| Dual stations (Single side)Dual stations (Dual sides) |

2440x750x900 | 2440x750x900 | ||

| 1800x750x900 | 1800x750x900 | |||

| 1220x1000x900 | 1220x1000x900 | |||

| Three stations (Single side) |

1500x750x900 | 1500x750x900 | ||

| Four pairs of gloves (single side) |

1800x750x900 | 1800x750x900 | ||

| Three stations (Single side) |

3660x750x900 | 3660x750x900 | ||

| Four stations (Single side) |

4880x750x900 | 4880x750x900 | ||

| Four stations (Dual sides) |

2440x1000x900 | 2440x1000x900 | ||

| Six stations (Opposite side) |

3660x1000x900 | 3660x1000x900 | ||

| 3660x1200x900 | 3660x1200x900 | |||

| Eight stations (Opposite side) |

4880x1000x900 | 4880x1000x900 | ||

| 4880x1200x900 | 4880x1200x900 | |||

| 12 stations (Opposite side) |

7320x1000x900 | 7320x1000x900 | ||

| Control System | Siemens S7 | Siemens S7 | Siemens S7 | |

| Touch screen | Siemens 7″ Touch Screen |

Siemens 7″ Touch Screen |

Siemens 7″ Touch Screen |

|

| Purifier | Single | Single | Double | |

| Blower | 90 m³/h | 90/145/180 m³/h | 90/145/180 m³/h | |

| Vacuum pump | 12 m³/h | 12/16 m³/h | 12/16 m³/h | |

| Moisture | <0.1ppm | <0.1ppm | <0.1ppm | |

| Oxygen | <0.1ppm | <0.1ppm | <0.1ppm | |

| Applications | R&D type For R&D in Universityand Laboratory |

Universal type For both R&D andsmall-scale production |

Production type For large-scale production |

|

| *Upure:With internet remote control and automatic antechamber door. | ||||

| *The above specification dimensions are the nominal dimensions of the glove box case | ||||

Product features of Mikrouna Glove Box:

(1) Informationization and Systematic Management:

Mikrouna has implemented a comprehensive information and system-based approach to manage all aspects of its operations, from design to after-sales, ensuring product quality, timely delivery, and efficient service.

(2) Advanced Production Equipment:

It possesses high-precision, full-range, and state-of-the-art equipment from reputable domestic and international brands, supporting product quality and enhancing production capacity.

(3) Customizable and Diverse Product Range:

Mikrouna offers a wide array of products that can be tailored to specific requirements, integrating various components like solvent adsorbers, furnaces, micro projection systems, etc. It also caters to the lithium battery industry with specialized equipment.

(4) Large-Scale, Standardized, and Modular Production:

Large-scale production facilitates bulk purchasing of parts, standardization ensures universal and interchangeable components, and modularity simplifies the production and assembly process.

(5) High-Quality Standards:

Products are manufactured adhering strictly to German and nuclear industry standards, matching or exceeding international benchmarks, and supplied to renowned global brands.

(6) Multi-Industry Applications:

Mikrouna’s products find use in diverse sectors like lithium battery R&D, physical and chemical research, powder metallurgy, nuclear technology, OLED/PLED research, pharmaceuticals, material processing, solar cells, 3D printing, fine chemicals, and polymer materials.

(7) Dew Point Analyzer with P205 Sensor:

This analyzer is suitable for corrosive environments and can be restored through cleaning and recycling, addressing the issue of disposal due to contamination.

(8) Oxygen Analyzer with ZrO2 Sensor:

The analyzer addresses the limitations of fuel cells by ensuring a longer lifespan and resistance to air exposure.

|

|

|

|

|

|

|

|

|

|

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.