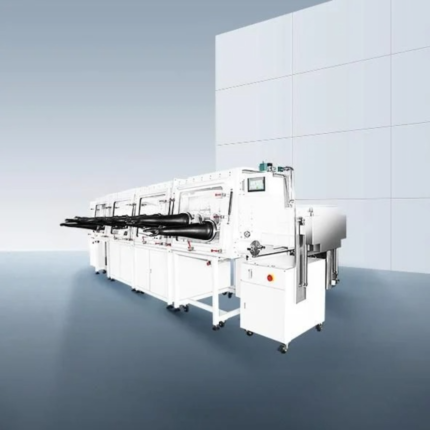

Solid State Battery Lithium Metal Anode Negative Electrode Making Machine

ithium metal anode making machine is applicable to the preparation and molding/shaping of lithium metal anode. It can perform lithium metal strip fixed-length cutting and copper strip fixed-length tab cutting, so as to realize (lithium electrode sheet+copper tab) pressing and making anode electrode process.

Automatically complete the fixed-length cutting of the lithium strip into pieces and the fixed-length cutting of the copper strip into electrode tabs Efficiency ≥15ppm, winding tension ≥1N.

Lithium strip low tension unwinding;

Fixed length traction and cut into sections;

CCD positioning & correction;

Copper tab cutting and transfer;

Tab and lithium foil pre-pressing and bonding;

Tab final pressing flat and compounding;

CCD detection and sorting;

Lithium electrode isolation and stacking transfer;

Lithium electrode sheet directly deliver into the stacking/lamination machine;

MES system connection function;

Lithium-copper Negative Electrode Sheet Making Machine is also optional in Mikrouna Lithium Metal Negative Electrode/Anode Making Machine

Introduction to the functions and principles of the equipment:

Lithium metal anode making machine is applicable to the preparation and molding/shaping of lithium metal anode. It can perform lithium metal strip fixed-length cutting and copper strip fixed-length tab cutting, so as to realize (lithium electrode sheet+copper tab) pressing and making anode electrode process.

This device completes the pole film production process of laminated lithium ion battery, plastic shapes the pole film and cuts it into slices, and then the pole slice is automatically collected. Manual winding installed on the air expansion shaft of the equipment, the equipment automatically winding, the correction mechanism for the winding process, and control the tension of the electrode sheet through the tension control system, the servo motor traction mechanism will transport the electrode sheet to the hardware mold for the pole ear cutting station with the continuous pole cutting into a single electrode sheet sent to the material box for collection.

Lithium Anode Manufacturing Process Mikrouna:

Incoing material size:

| Material (mm) | Thickness (mm) | Width (mm) | Height (mm) | Foil thickness (μm) | Material roll diameter (mm) | Material bin diameter | |

| 1 | Positive electrode sheet | 0.06~0.3 | 80~200 | 100~300 | 10~25 | ≤φ 400mm | 6 Inch |

| 2 | Negative electrode piece | 0.06~0.3 | 80~200 | 100~300 | 5~12 | ≤φ 400mm | 6 Inch |

Requirements for production and incoming materials; Electrode sheet winding error: ±1mm; Electrode sheet wave: X≤1mm/m;

Ensure the life of the mold, the thickness of the mold is less than 10 μm;

Functional parameters and general requirements:

(1) Use environment instructions

| Item | Environmental description | Remarks | |

| 1 | Humiture | Temperature: 25±3℃, humidity: 30%; | |

| 2 | Cleanliness | Level 100,000; | |

| 3 | Factory ceiling and load-bearing conditions | Ceiling to 3m, ground gold steel sand treatment, bearing: 1t / m2; | |

| 4 | Power supply | 380V/50 HZ (within 10% of voltage volatility), three-phase five-wire power supply; | |

| 5 | Cooling water | 0.1MPa~0.3MPa, 7~17℃; | |

| 6 | Compressed air | 0.5~0.7MPa; | |

| 7 | Normal temperature nitrogen | 0.5MPa, purity> 99.9%; |

(2) Key parameters of equipment

| Item | Requirement | Description | |

| 1 | Yield rate | ≥99% | |

| 2 | Equipment failure rate | ≤2.0% | The percentage of the fault downtime and the start time of the equipment is an indicator of the technical status, fault level, maintenance quality and efficiency; the fault downtime refers to the time when the fault starts to the first qualified product output; the load time refers to the time when the equipment should start as planned, generally calculated as 24H per day; data collection requires the average of data of 30 days of continuous production; the failure rate of single equipment = stop time of single equipment, fault load time*100%; |

| 3 | Utilization rate | ≥98% | Each shift calculation, including the necessary daily day maintenance and material installation time; |

| 4 | Production efficiency | ≥40PPM

(80 in width ~ 200 mm); |

|

| 5 | Transverse burr, Vk | ≤10μm |  |

| 6 | Longitudinal burr, V h | ≤12μm | |

| 7 | Electrode sheet cutting width accuracy | ±0.2mm | |

| 8 | Electrode sheet cutting height precision | ±0.25mm | (Cutting bottom edge condition) |

| 9 | Mold lifespan: | ≥ 1 million times | Can repair molds more than 10 times, with a total lifespan>1 million times; |

| 10 | Cut blade life | ≥ 1 million times | Can repair molds more than 10 times, with a total lifespan>1 million times; |

(3) Product dimensions and errors

| Item | Designation | Range |

| Lithium foil height | H1 | 60~160mm;±0.2 |

| Lithium foil width | W1 | 60~100mm;±0.2 |

| Copper tab height | H2 | 15~25mm;±0.5 |

| Copper tab width | W2 | 5~30mm;±0.2 |

| Tab recombination depth | D1 | 3~10mm:±0.5 |

| Tab height | H2 | 10~20mm;±0.5 |

| Angle A | A | 90°±0.1° |

| Angle B | B | 90°±0.1° |

(3) Incoming materials and functional technical parameters

| Item | Specification requirements | |

| Lithium foil coil specifications | Thickness | 40-120μm |

| Width | 60-100mm | |

| Outside diameter | 300mm | |

| Core inner diameter | 20mm | |

| Isolated sheet | Yes | |

| Copper tape coil specifications | Thickness | 6-10μm |

| Width | 10-30mm | |

| Outside diameter | 200mm | |

| Core inner diameter | 3in | |

| Slitting method | Lithium | Alloy cutter |

| Copper | Alloy cutter | |

| Lithium copper composite strip | Metal die cutting and alloy cutting knife | |

| Number of consecutive slitting times | Copper | ≥50000 |

| Lithium | ≥500 | |

| Lithium copper composite strip | Mold ≥10000, cutting knife ≥10000 | |

| Anode electrode transfer mode | No/micro-deformation transfer | |

| CCD quantity | ≥1/ Before product is loaded into magazine | |

| CCD identification content | Missing Angle, tab position, right Angle | |

| NG product exclusion function | exclude | |

| Receiving form | Automatic blanking to isolating sheet box | |

| Capacity | 2~4ppm | |

(4) Overall overview and operating environment requirements

| Item | Installation requirements |

| Equipment storage location, load and area | About 5000kg, area about 6000*1600*2200mm(length * width * height) |

| Electrical (220/380) power | 380V/about15KW |

| Gas (nitrogen, compressed air, vacuum, etc.) | Compressed air 0.5~0.7Mpa, 20L/min; Vacuum source: ≤-0.09MPa 120L/Min |

| Temperature/humidity | 20~23±2℃/ Dew point below -45℃ |

| Environmental protection and safety | Access control and electric self-locking protection |

| Cleanliness/dryness | 100-300 thousand class |

FAQ

Q: What are the unique technical features of Mikrouna’s lithium-metal solid-state battery equipment?

A: Our equipment employs advanced solid-state electrolyte preparation technology, enabling high-precision membrane deposition that ensures uniformity and stability of the electrolyte membrane. Additionally, it boasts efficient electrode coating and packaging processes, enhancing battery performance and consistency.

Q: How efficient is Mikrouna’s lithium-metal solid-state battery equipment in production?

A: Our equipment is meticulously designed and optimized for high production efficiency while maintaining product quality. Through automation control and advanced process flows, we significantly reduce production cycles to meet large-scale market demands.

Q: How is the stability and reliability of the equipment ensured?

A: We use high-quality components and materials, subject them to rigorous quality inspections. Extensive reliability testing and optimization are conducted during R&D, complemented by comprehensive after-sales service and technical support to guarantee long-term stability and reliability.

Q: What are the energy-saving advantages of Mikrouna’s equipment?

A: Our equipment adopts an energy-efficient design concept, effectively reducing energy consumption during operation. By optimizing the power system and energy management, we minimize unnecessary energy waste, helping users lower production costs.

Q: Are the operation and maintenance of the equipment complex?

A: We strive to provide user-friendly equipment with a simple and intuitive operation interface, requiring minimal training for operators. Detailed maintenance manuals and training services are also provided to facilitate easy routine maintenance and care.

Q: How does Mikrouna ensure the quality of lithium-metal solid-state batteries produced by its equip

A: The equipment is equipped with high-precision detection and monitoring systems to real-time monitor key production parameters. Coupled with a rigorous quality control system, every batch of products undergoes strict testing to meet high-quality standards.

Q: What about customization services for the equipment?

A: We offer customized equipment solutions tailored to clients’ specific needs and production scales. Whether for small R&D lines or large-scale production lines, we can design the most suitable equipment configurations.

Q: What safety considerations have been incorporated into Mikrouna’s equipment?

A: The equipment features multiple safety protection mechanisms, including overvoltage and overcurrent protection, as well as fire and explosion-proof designs. Adherence to relevant safety standards and regulations throughout production ensures the safety of operators and equipment.

Q: How does Mikrouna handle equipment upgrades and replacements?

A: We continuously invest in R&D, keeping abreast of industry trends and market demands to upgrade and improve our equipment. Upgrade services are provided to ensure that clients’ equipment remains advanced and competitive.

Q: Compared to competitors, what are the advantages of Mikrouna’s equipment?

A: Our equipment excels in technological innovation, performance stability, production efficiency, customization services, and after-sales support. By continuously enhancing our technical capabilities and service levels, we provide clients with more valuable lithium-metal solid-state battery production equipment.

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.