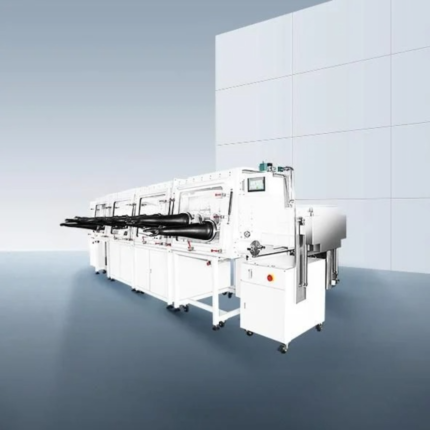

All-Solid-State-Battery Pouch Cell Dry Preparation Pilot Line

Designed for cutting-edge research and development in solid-state battery technology. Our glove boxes maintain H2O and O2 levels below 1PPM, ensuring safety and stability throughout the battery manufacturing process in the SSB pilot line.

The Mikrouna Solid-State Battery Pilot Line employs advanced dry and wet processes to ensure the high-performance manufacturing and stability of solid-state batteries.

Additionally, our SSB pilot line is fully customizable, making it ideal for supporting batteries with different material systems, including lithium metal anode, Polymer, oxide, and sulfide solid-state batteries.

Main sections:

– Preparation of Solid Electrolyte Materials: Precise weighing & proportioning, vacuum stirring;

– Preparation of Electrolyte Membranes: 3D printing molding / extrusion coating, roll pressing;

– Preparation of Electrode Sheets: Coating & baking, die-cutting & shaping, pressing copper tabs onto lithium foil;

– Assembly of Solid-State Batteries: Semi-automatic stacking, hot pressing test, ultrasonic welding, top & side sealing, vacuum electrolyte filling & sealing.

Integrating Lithium metal electrode preparation, stacking, welding, packaging, insulation

detection, vacuum electrolyte injection, and sealing functions;

The transition chamber also has a vacuum baking function;

Water and oxygen content atmosphere for the Lithium metal solid state battery line inside the glove boxes are controlled below 1ppm.

Mikrouna All-Solid-State-Battery Pouch Cell Dry Preparation Pilot Line

1. Overview:

Leveraging the core technological advantages of its equipment, the small-scale pilot line for the dry process manufacturing of all-solid-state battery pouch cells can achieve processes such as material fibrillation, film formation, lamination, cutting, stacking, tab welding, encapsulation, and cell densification, thereby completing the entire production process of all-solid-state batteries.

Mikrouna is capable of providing customers with complete line solutions, including the entire line of equipment (with a full-process atmosphere protection system for the preparation of sulfide-based all-solid-state batteries), dry process-specific material kits, dry process toolkits, and a comprehensive set of process documentation. These solutions can fully meet customers’ diverse needs for material validation, process validation, and small-scale production trials, helping customers to rapidly prototype dry process all-solid-state batteries with minimal viable solutions.

2. Scope of Application and Equipment Features

This scheme can be used for the preparation of all-dry self-supporting membranes for cathode, anode, and solid-state electrolyte (oxide, sulfide) materials, as well as the preparation of dry multilayer composite electrode sheets, tab welding, stacking, packaging, and testing.

All equipment within this system is specially designed to be compact and can be freely operated within a glove box. The minimum starting material required is only 10-20g, significantly reducing the cost of preparing sulfide all-solid-state batteries in the laboratory.

This system can form a continuous bulk-phase fibrous network of PTFE material in just 3-5 minutes, boasting fast speed, high efficiency, and good uniformity.

During the membrane compositing stage, the Mikroluna dry electrode membrane preparation and compositing equipment can achieve continuous and efficient membrane formation of electrode materials and integrated compositing with current collectors, capable of producing cathode and anode electrode sheets with thicknesses ranging from 70 to 500 micrometers.

The sulfide electrolyte membrane preparation equipment can continuously produce sulfide electrolyte membranes with a thickness of 20 micrometers. The high-precision roller pressing systems equipped in both can ensure that the uniformity of the membrane thickness is less than 2 micrometers.

3. Advantages of the Dry Process Small-Scale Pilot Line Complete Solution:

– Time and Material Savings, Rapid Validation:

The compact equipment requires a small amount of material, reducing the cost of material process validation.

– Highly Integrated, Easy to Operate:

It integrates full-process dry preparation equipment for all-solid-state batteries, featuring a compact structure and easy operation.

– Focused on Dry Manufacturing Processes for All-Solid-State Batteries, Compatible with Sulfide-Based Batteries:

The production line is equipped with an atmosphere protection system to ensure high ionic conductivity of sulfide solid electrolytes throughout the entire production process.

– Provision of Dry Process Specialty Material Kits:

Mikrouna provides customers with specialty materials for dry preparation (including specialty PTFE and current collectors) to facilitate easier experimental work.

– Provision of Dry Process Technical Documentation Kits:

Mikrouna offers technical support to customers in material selection, process parameters, workflows, operating guides, etc., providing verified dry process parameters and experimental manuals to help customers start production as soon as possible.

– Provision of Dry Process Experimental Toolkit (Total of 29 Tools):

Mikrouna supplies customers with a specialty toolkit for dry process experiments, reducing the cost of selecting experimental tools, shortening validation time, and improving development efficiency.

– On-Site Training and Experimental Assistance:

Mikrouna provides comprehensive after-sales service and technical support, including on-site training and experimental assistance.

– Provision of Dust Control and Renovation Solutions for Dry Labs:

Mikrouna offers dust control and renovation solutions for laboratories, assisting customers in quickly setting up an environment suitable for trial production of dry all-solid-state batteries and starting production as soon as possible.

– Cost Reduction and Efficiency Enhancement, High Cost-Performance Ratio:

Process simplification and equipment optimization can further reduce customer investment costs and lower maintenance and operating costs of the production line.

4. Composition of program equipment

| Process | Product name |

| Mixing | High-speed mixing and shearing machine |

| Fibrosis | High-speed mixing and shearing machine |

| The electrode is film-formed | Film-forming composite machine |

| Electrode compounding | Film-forming composite machine |

| Rolling | Roller press |

| Die-cutting of electrodes | Manual electrode die-cutting machine |

| Stacking | Semi-automatic stacking machine |

| Tab welding | Ultrasonic tab welding machine |

| Hot press test | Hot press testing machine |

| Aluminum-plastic film punching shell | Aluminum-plastic film shell punching machine |

| Top side seal | Top side edge banding machine |

| Final seal | Vacuum sealer |

FAQ

Q: What are the unique technical features of Mikrouna’s lithium-metal solid-state battery equipment?

A: Our equipment employs advanced solid-state electrolyte preparation technology, enabling high-precision membrane deposition that ensures uniformity and stability of the electrolyte membrane. Additionally, it boasts efficient electrode coating and packaging processes, enhancing battery performance and consistency.

Q: How efficient is Mikrouna’s lithium-metal solid-state battery equipment in production?

A: Our equipment is meticulously designed and optimized for high production efficiency while maintaining product quality. Through automation control and advanced process flows, we significantly reduce production cycles to meet large-scale market demands.

Q: How is the stability and reliability of the equipment ensured?

A: We use high-quality components and materials, subject them to rigorous quality inspections. Extensive reliability testing and optimization are conducted during R&D, complemented by comprehensive after-sales service and technical support to guarantee long-term stability and reliability.

Q: What are the energy-saving advantages of Mikrouna’s equipment?

A: Our equipment adopts an energy-efficient design concept, effectively reducing energy consumption during operation. By optimizing the power system and energy management, we minimize unnecessary energy waste, helping users lower production costs.

Q: Are the operation and maintenance of the equipment complex?

A: We strive to provide user-friendly equipment with a simple and intuitive operation interface, requiring minimal training for operators. Detailed maintenance manuals and training services are also provided to facilitate easy routine maintenance and care.

Q: How does Mikrouna ensure the quality of lithium-metal solid-state batteries produced by its equip

A: The equipment is equipped with high-precision detection and monitoring systems to real-time monitor key production parameters. Coupled with a rigorous quality control system, every batch of products undergoes strict testing to meet high-quality standards.

Q: What about customization services for the equipment?

A: We offer customized equipment solutions tailored to clients’ specific needs and production scales. Whether for small R&D lines or large-scale production lines, we can design the most suitable equipment configurations.

Q: What safety considerations have been incorporated into Mikrouna’s equipment?

A: The equipment features multiple safety protection mechanisms, including overvoltage and overcurrent protection, as well as fire and explosion-proof designs. Adherence to relevant safety standards and regulations throughout production ensures the safety of operators and equipment.

Q: How does Mikrouna handle equipment upgrades and replacements?

A: We continuously invest in R&D, keeping abreast of industry trends and market demands to upgrade and improve our equipment. Upgrade services are provided to ensure that clients’ equipment remains advanced and competitive.

Q: Compared to competitors, what are the advantages of Mikrouna’s equipment?

A: Our equipment excels in technological innovation, performance stability, production efficiency, customization services, and after-sales support. By continuously enhancing our technical capabilities and service levels, we provide clients with more valuable lithium-metal solid-state battery production equipment.

Reviews

Clear filtersThere are no reviews yet.