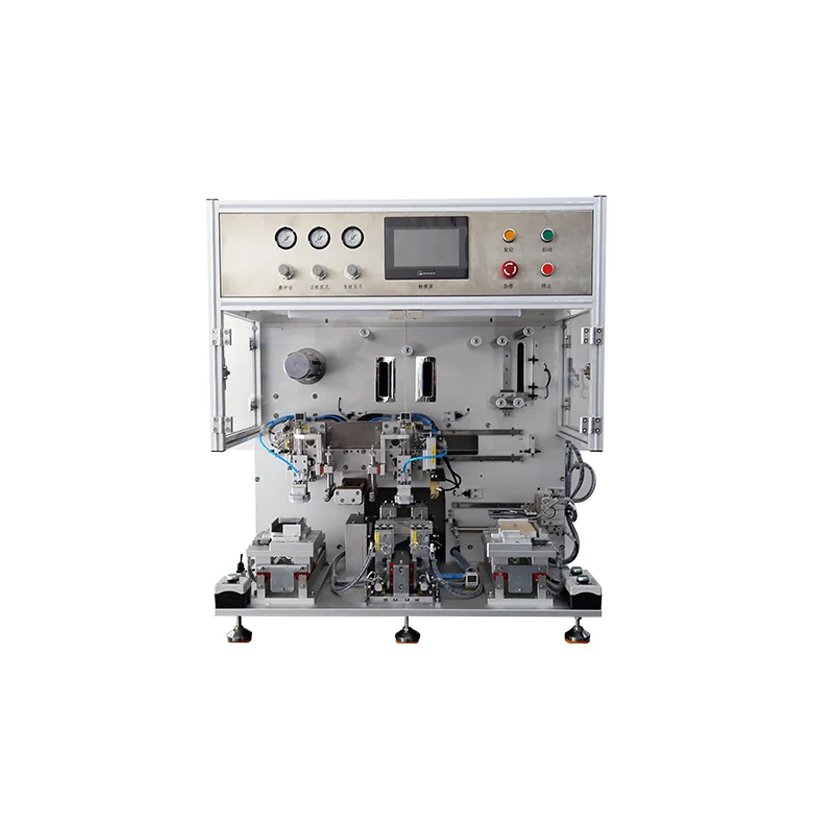

Lithium Metal Battery Pilot Line Automatic Stacking Machine

The Z-shaped lithium metal battery stacking machine is a pivotal piece of equipment in the mid-stage production process of lithium battery manufacturing. Lithium metal battery production can be broadly divided into four major processes: electrode sheet production, cell assembly, cell activation and testing, and module/Pack encapsulation. Among these, cell assembly constitutes the mid-stage production, encompassing processes such as winding or stacking, cell pre-encapsulation, and cell electrolyte injection. Stacking, in particular, involves arranging individual electrode sheets produced in the die-cutting process into a cell.

The Z-shaped stacking machine stands out in the market as one of the four main types of stacking equipment, alongside cut-and-stack machines, thermal bonding stacking machines, and winding-stacking integrated machines. Currently, the Z-shaped stacking machine is the most widely applied in China due to its efficiency and reliability.

Technical Characteristics and Advantages:

– High Precision and Efficiency:

The Z-shaped stacking machine utilizes precision mechanisms to ensure accurate alignment and stacking of electrode sheets, thereby enhancing production precision. Its efficient stacking process significantly boosts production throughput.

– Enhanced Battery Performance:

Compared to winding processes, stacking offers several advantages. Firstly, stacked cells exhibit a higher volumetric energy density, with an increase of approximately 5% under the same cell design volume. Secondly, stacked cells possess a more stable internal structure and higher safety, as they are free from uneven internal stresses at corners, reducing the risk of cracks and enhancing battery lifespan.

– Adaptability and Flexibility:

The Z-shaped stacking machine is capable of producing a wide range of battery sizes and shapes, making it ideal for high-rate, large-size, and irregular-shaped batteries. This adaptability caters to the diverse needs of the lithium battery market.

– Consistent Quality:

With precise control over the stacking process, the Z-shaped machine ensures uniform tension on separators, maintaining consistent porosity and material properties, thereby contributing to high-quality battery production.

Operational Principle:

In the die-cutting process preceding stacking, electrode sheets are cut into individual pieces using a single-sided die-cutting method, resulting in uniform electrode ears. These sheets are then fed into the Z-shaped stacking machine. The machine employs a Z-shaped path to alternately stack positive and negative electrode sheets, ensuring precise alignment and forming a complete cell.

Market Trends and Future Prospects:

As the global trend shifts towards square large-size batteries, the application of stacking technology is expected to expand significantly. The Z-shaped stacking machine, with its proven reliability and efficiency, is poised to play a crucial role in this transition. According to industry projections, by 2027, the battery production capacity utilizing stacking equipment will reach 845 GWh, corresponding to a market size of approximately 31.9 billion yuan for stacking machines, with a compound annual growth rate (CAGR) of 35% over the next five years.

In conclusion, the Z-shaped lithium battery stacking machine represents a significant advancement in lithium battery manufacturing technology. Its combination of precision, efficiency, and adaptability makes it a key player in the industry’s pursuit of higher energy densities, safer batteries, and more versatile product offerings.

| Item | Semi-auto Type |

| Outer diameter of separator material roller | <Φ200mm |

| Inner diameter of material roller | 3″ |

| Width of separator material | 50-300mm |

| Thickness of separator material | 0.02-0.04mm |

| Stacking speed | 4~6 seconds / sheet (positive / negative electrode) |

| Active unwinding of separator | Working tension 10N~30N adjustable |

| Separator stacking accuracy | Cell thickness 5-20 ≤ ±0.3mm (end to end homogeneity) |

| Electrode sheet stacking accuracy | Cell thickness 5-20 ≤ ±0.3mm (central deviation value) |

| Combination accuracy of separator and electrode sheet | Cell thickness 5-20 ± 0.3 mm (central deviation value) |

| Equipment running rate | 95% |

| Product qualified rate | 98% |

| Product Details | |

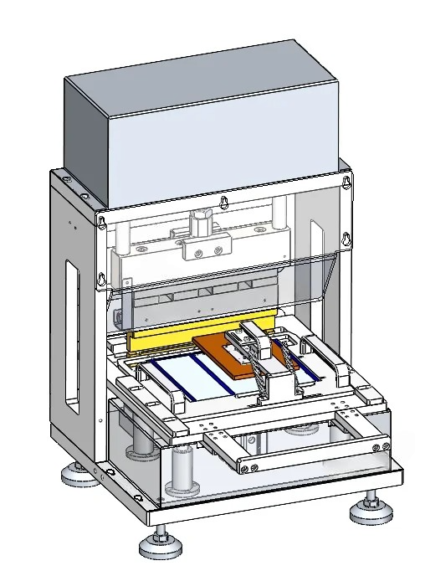

| Mechanical arm for taking electrode | 1.Precise, high speed and stable operation between the trough and the stacking table.

2.Taking and discharge material in vacuum is stable and reliable , it equipped with vacuum meter to detect vacuum degree. Vacuum meter can be set and adjusted according to actual needs, and has the function of recording and taking materials. |

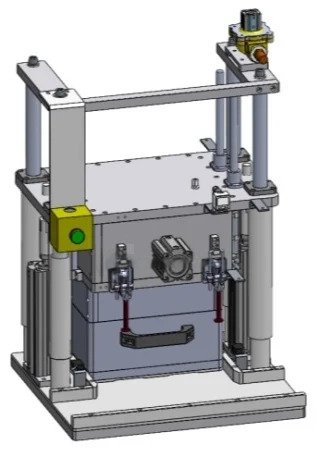

| Separator unwinding, correction, tension mechanism | 1.The separator tension is controlled by the floating roller and the low friction cylinder to make the separator tension keep constant and the battery tension uniform and consistent.

2.Separator can automatically correct. |

| Cathode electrode storage box

|

1.The cathode electrode is a single tank configuration, which can put multiple layers of sheet material.

2.Automatic stop alarm when there is no material in the trough. Manually replace the trough. |

| Anode electrode table

|

Put the anode electrode single sheet material box on the table. The material box is positioned by the dowel pin, accurate and reliable.

|

| Positioning mechanism

|

1.The single piece of cathode and anode electrode is precisely positioned to ensure the alignment accuracy between each layer of the cell.

2.Because of the material characteristics of the anode electrode, the material box is manually switched. 3.With missing electrode detection and prompt function. |

| Stacking mechanism

|

1.Pneumatic circuit is used to control the action of each claw, and servo motor drives the stacking table to adapt to different layers of cells. The pressure of the claw can be adjusted by the precision pressure regulating valve.

2.The servo electric drive is used to make it move in high speed, accurate and stable between the positive and negative electrode taking mechanical arms. 3.Four independent cylinders drive the press claw to make X-Y bi-directional compound movement, press and position the pole plate and separator, and realize the Z-shaped lamination assembly process of the positive and negative electrode plate and separator to form the battery cell. |

FAQ

Q:Do you provide after-sales service?

A:Yes, our engineers available to service machinery overseas.

Q: What quotation to use?

A:General FOB quotation, other quotations can also be negotiated.

Q: In case of FOB quotation, the factory is responsible for which port to ship to?

A:Shenzhen Port.

Q:Full set of lithium battery equipment, for example:

A:Mixing machine-coating machine-rolling machine-slitting machine-stacking machine-Die cutting machine-welding machine–packaging machine –injection machine–degas machine, etc.

Q:If I want to customize the equipment, how long does it take?

A:We can provide customized services for our customers. It usually takes about 90-120 days, depending on the specifications of the customized equipment.

Q:Are you a manufacturing factory or trading company?

A:We have 3 modern manufacturing factories in Shanghai, Hubei and Dongguan of China.

Q:How to buy?

A:Simply contact our sales and inform your demands, request for a Proforma Invoice. The order will be shipped after receipt of all payment.

Q:How can I trust you?

A:Always warmly welcome for visiting our factory. Or have video call. Or arrange any of your friend to come and help you check our factory. Or any other good idea you can feel free to inform. We will do our best to cooperate. We are serious supplier in this industry for a long time. You can always rely on us.

Q:How is your warranty?

A:12 months trouble-free warranty from the date of acceptance of the equipment, during which the supplier is responsible for free remote guidance maintenance equipment. For the parts that need to be replaced during the warranty period, the transportation cost is paid by the buyer before delivery.

Q:How is your technical support?

A:Online technical support is provided free of charge during the warranty period, and offline technical support is chargeable.

No PDF available for this product.

Reviews

Clear filtersThere are no reviews yet.